FoodJet at the IBA Trade Fair 2023

During this year's IBA Trade Fair FoodJet is showcasing two brand-new depositors. Each with their own application. Let us tell you all about our depositors.

Watch this video to see our two depositors live in action at the iba fair 2023. Dirk will tell you everything you need to know about these brand-new depositors! More information about these depositors can be found on this page.

Want to learn more about the possibilities with the FoodJet depositors?

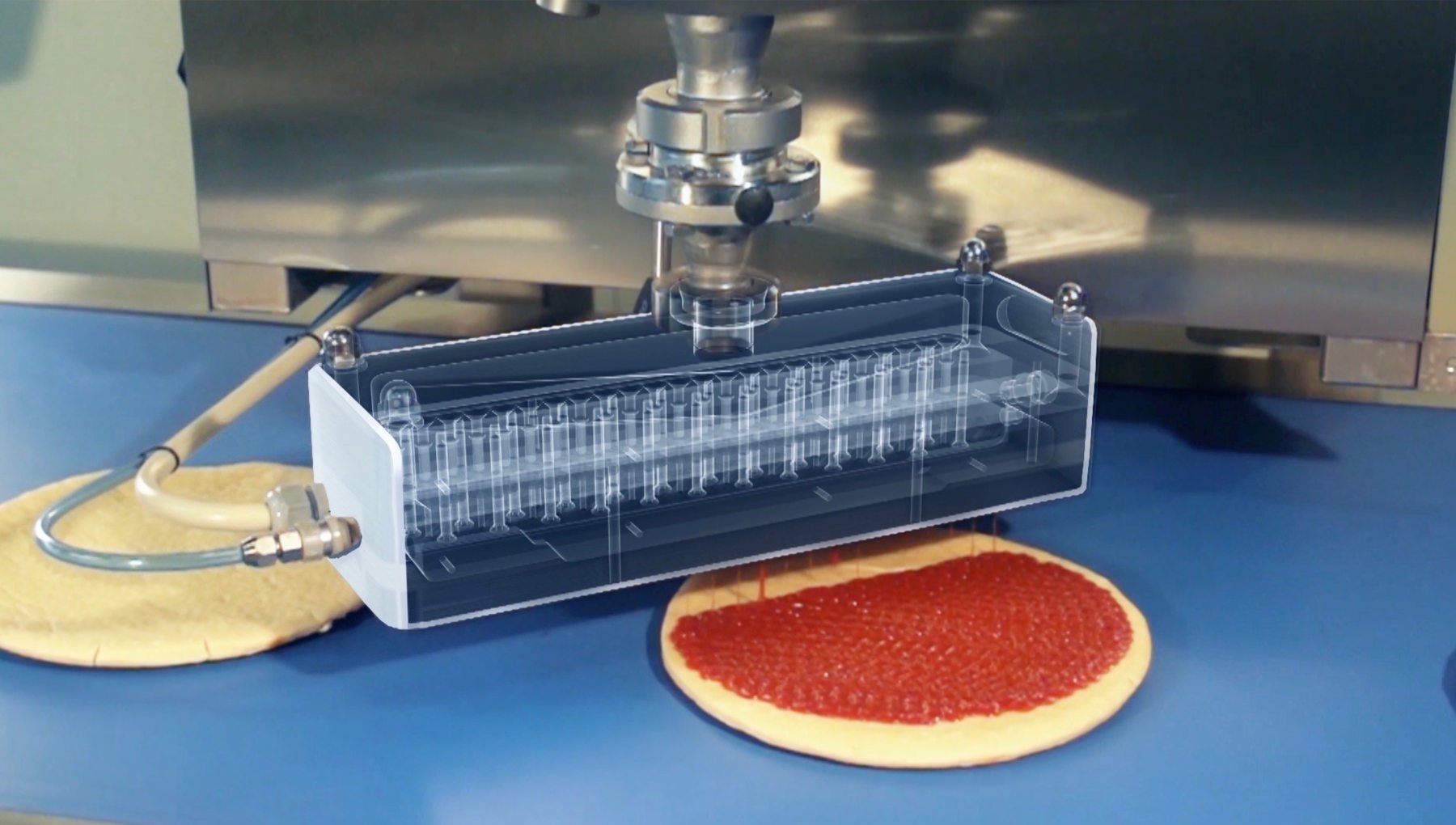

FoodJet MDMV pizza sauce depositor

The latest addition to the line of FoodJet pizza sauce depositors is packed with great new features that will blow your mind!

- Unparalleled sauce distribution accuracy. Witness a level of sauce distribution precision that will leave you speechless. Two sauce entrances make sure that the material is distributed evenly throughout the complete depositing head.

- Effortless cleaning. Cleaning has been made easier and more thorough. No more dismantling parts, no more time-consuming scrubbing. Cleaning is now a breeze, and dare we say, even enjoyable! The complete system is cleaned and flushed with just one exit that goes straight to the drain. Simple and very effective.

- Real-time adjustments. You want to change the amount of sauce or the pattern in which sauce is deposited? Why not do it on the fly and see the results straight away? No problem for the new FoodJet Control Platform.

- Next level software controls. From energy consumption through statistical data, everything is monitored and controled so that you can take control of your process.

- Flexible sauce supply. Whether you run one sauce all day long and feed the system through a ring line or you change more frequently and prefer a sauce supply skid. Everything is possible and ready for operation.

The FoodJet MDMV comes in two models: 300 or 2 x 300. The first supplies material up to an effective width of 300mm. It uses the new FJ31 depositing head that has 36 nozzles. The 2 x 300 model has two FJ31 depositing heads. If both heads connect the effective printing width is 600mm. However, both heads can also be used on dedicated product lanes with a wider pitch. In that case, each lane can have a maximum effective width of 300mm.

Contact us to find out more about this small footprint powerhouse.

Depositing sauces like no other

The brand new FoodJet MDSPT is our entry-level food depositor. But don't let the small footprint fool you. This depositor has what it takes to give a great performance. Whether you run small production runs or a single-lane continuous, we got your back.

- Entry-level but full-options. The MDSPT is operated with FoodJet Designer Studio. This software gives you a lot of possibilities to create the exact pattern you are looking for

- Small yet versatile. There is no need for any mechanical changeover when you switch from one product size or shape to another. It is all in the software!

- High-quality depositor. Allthough the MDSPT is our entry-level depositor, it is still build in the FoodJet quality that will guarantee years and years of operations.

- Inclusions? Yes, please. You can use the MDSPT with a wide range of depositing heads and various nozzles sizes of up to 8mm. That will give you the flexibility to run all the sauces you need.

The MDSPT can be executed with one FJ26 or FJ32 depositing head. The effective depositing width is ±200mm, depending on the required level of detail and the material. The depositor can run both in continuous and batch operation.

Contact us to find out more about this versatile depositor.

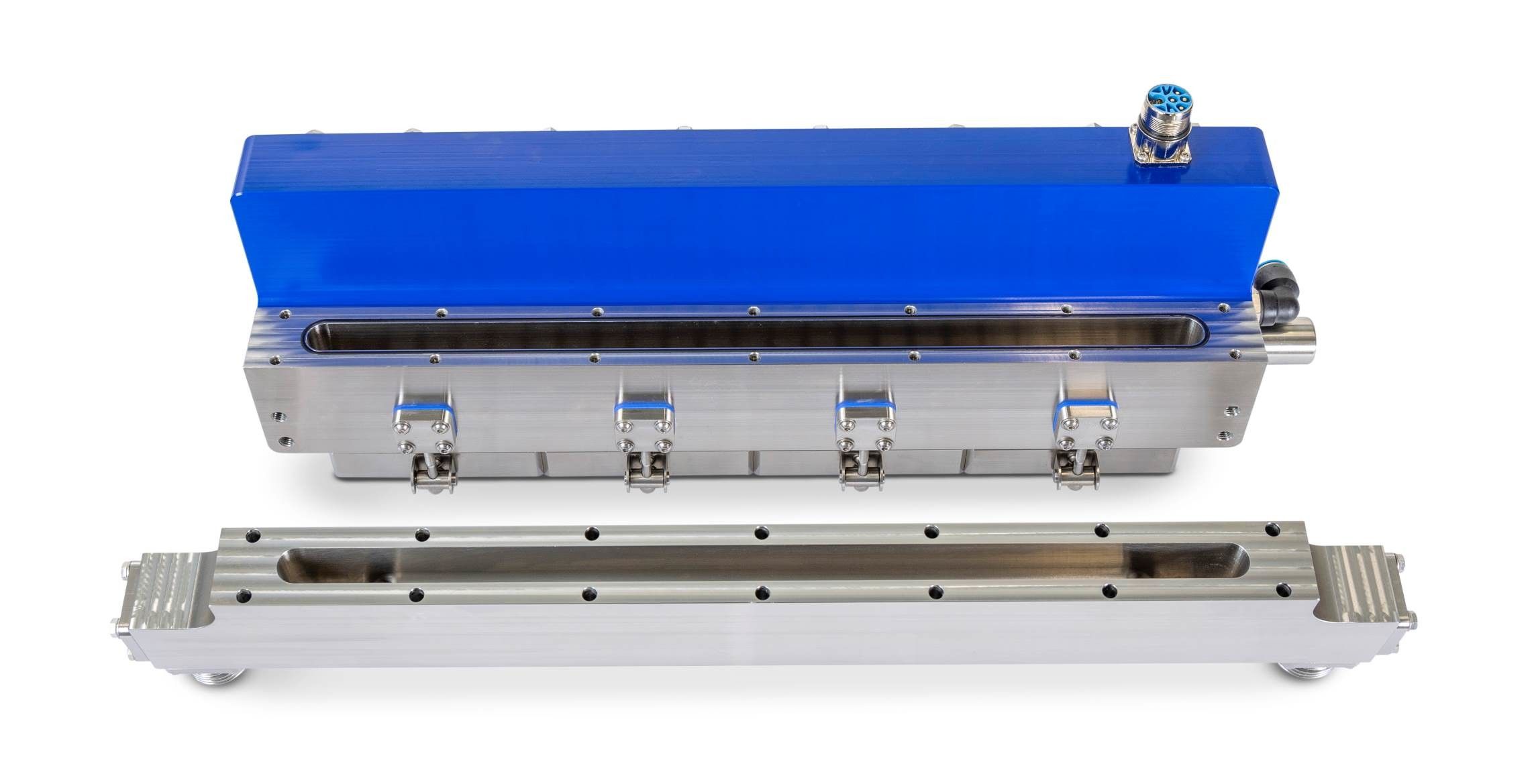

The all new FoodJet workhorse: FJ32

This FJ32 depositing head is the new workhorse in the FoodJet program. It is loaded with a lot of upgrades you have been asking for:

- Easy to change cartridges. The easy click-on and click-off nozzle cartridges make maintenance a lot easier and faster.

- Nozzle upsize and downsize. Greater flexibility to size down, and up again, the nozzle diameter. It is just a matter of changing cartridges.

- Suitable both for warm and cold materials. The FJ32 can handle both warm and warm materials if the supply system is engineered to do so.

- Ready for higher resolutions. The nozzle pitch has been considerably reduced. This makes it possible to achieve a very high print resolution for excellent results.

About FoodJet

FoodJet is the leading company in precision depositing of liquid foodstuff. Since the turn of the century we offer our services to the bakery and confectionary industry. We are always one step ahead when it comes to helping our clients solve their depositing challenges. Supplying our systems to the leading food processors in the world, more and more companies trust FoodJet with improving their product quality and decreasing their cost of production.

Our team

With a team of 40 professionals, we are focused on engineering and developing innovative systems for depositing liquid patterns. Our team is dedicated to create answers to depositing challenges that existing equipment cannot solve.