Targeted depositing: upgrade your traditional production line

In the dynamic world of food production, the challenges of depositing low-viscosity foodstuffs are numerous. Traditional depositing technologies often fall short in precision, efficiency, and waste reduction. This is where FoodJet steps in, offering a solution that not only addresses these challenges but innovates the way food products are enhanced.

The challenges in targeted food depositing

In your production line, you might have encountered various issues with standard depositing technologies. Common problems are:

- Inconsistent distribution,

- high levels of waste, and

- limited flexibility in design.

These challenges not only affect the efficiency of your production but also lead to increased costs and have an effect on the product quality. Whether it's uneven application of sauces or the inability to create complex designs, the limitations of traditional depositors can hinder your ability to meet market demands and customer expectations.

The benefits you gain with FoodJet's targeted application technology

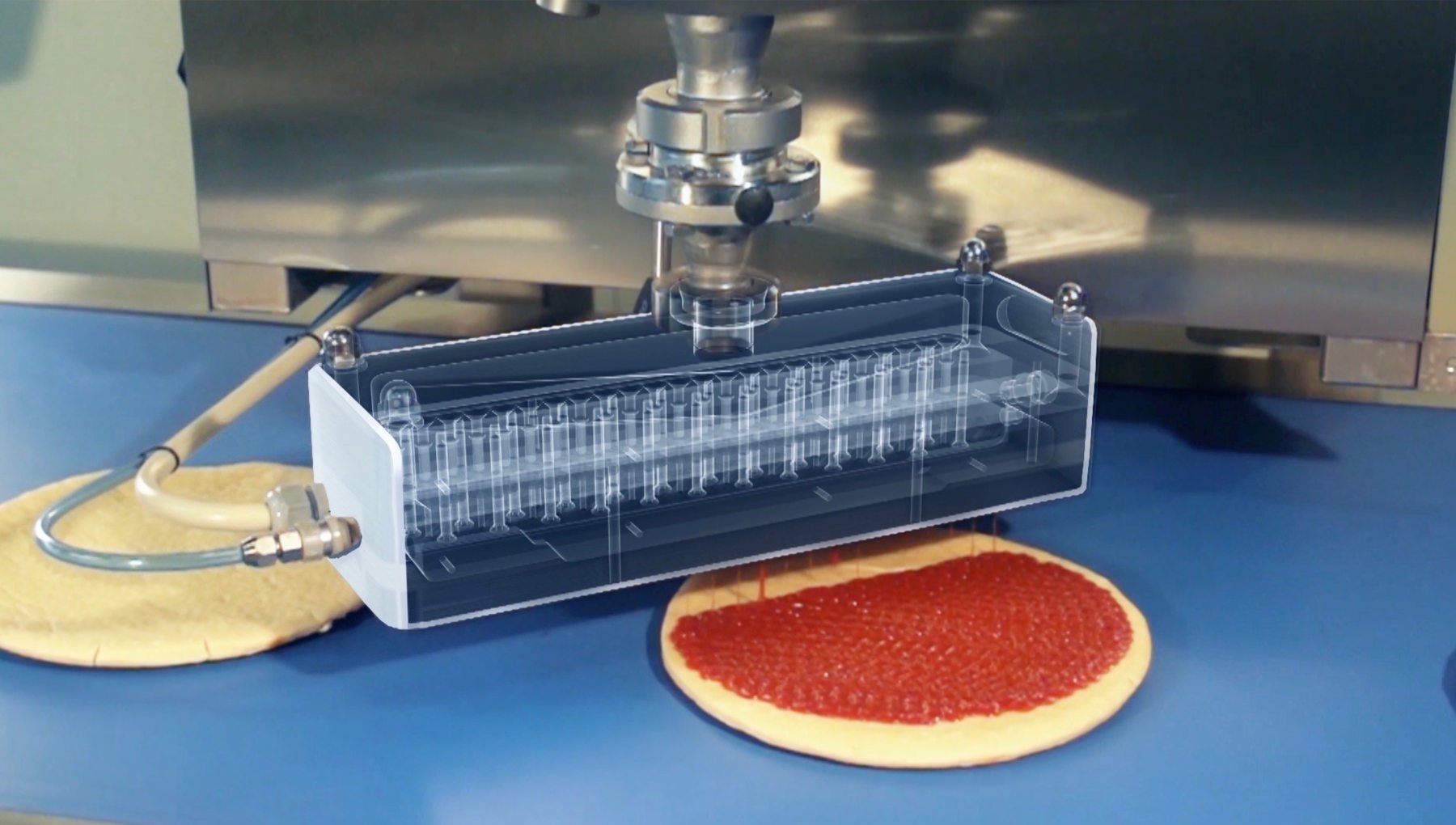

Imagine a depositor that offers precise, customizable deposition with consistent distribution, significantly reducing waste and seamlessly integrating into your existing production processes. FoodJet's targeted depositing technology is designed with your needs in mind.

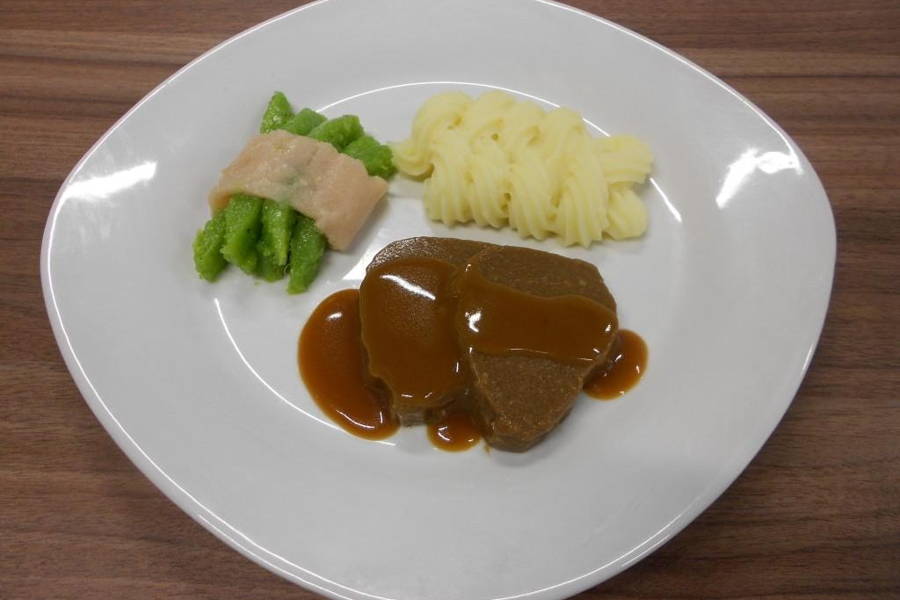

FoodJet's targeted application is specifically designed to handle low-viscosity foodstuff with high precision. Our depositors are designed to accurately deposit these solutions onto your products, ensuring consistent coverage and enabling customizations. Whether it's fat compound, tiger paste, jam or chunky sauce, our technology guarantees precise application, enhancing the overall quality and presentation of your products.

How FoodJet's targeted depositor addresses your needs

Our targeted depositor is not just a machine; it's a solution to your production challenges. With its precise and customizable deposition capabilities, it opens up new opportunities for food manufacturers. You can now deposit sauces, toppings, glazes, and coatings with unmatched accuracy and consistency.

This technology is ideal for creating graphical decorations, filling cavities, and providing uniform surface covering on various food products. It ensures that each product receives the desired pattern or layer, enhancing both visual appeal and taste.

Three targeted depositing applications

FoodJet's targeted depositors are divided into three main solutions, each addressing specific needs in your production line:

- Graphical decorations: Create personalized graphical designs on food products with precision. Our advanced vision technology ensures consistent appearance, whether you're applying seasonal figures or patterns using materials like tempered chocolate or fat compound has never been this easy.

- Cavity filling: Overcome the challenges of filling cavities in food products. Our depositors, equipped with advanced vision technology and flexible precision systems, ensure accurate and consistent filling, a task that traditional technologies struggle with. Especially if products are not aligned or even rotated, FoodJet finds each cavity and deposits the material straight on target.

- Surface covering: Achieve even and uniform surface covering of food products. Our targeted application is specifically designed to apply materials in an even layer, adapting to any shape of product with our accurate vision technology.

About FoodJet

As a leader in targeted depositing of liquid foodstuff, FoodJet has been at the forefront of innovation since the turn of the century. We cater to the bakery and confectionery industry, constantly striving to solve depositing challenges. Leading food processors worldwide use FoodJet to upgrade their production process. Become part of the growing number of companies that trust FoodJet to enhance their product quality and reduce production costs.

Would like to receive our articles and updates?

Sign up for the FoodJet Newsletter.