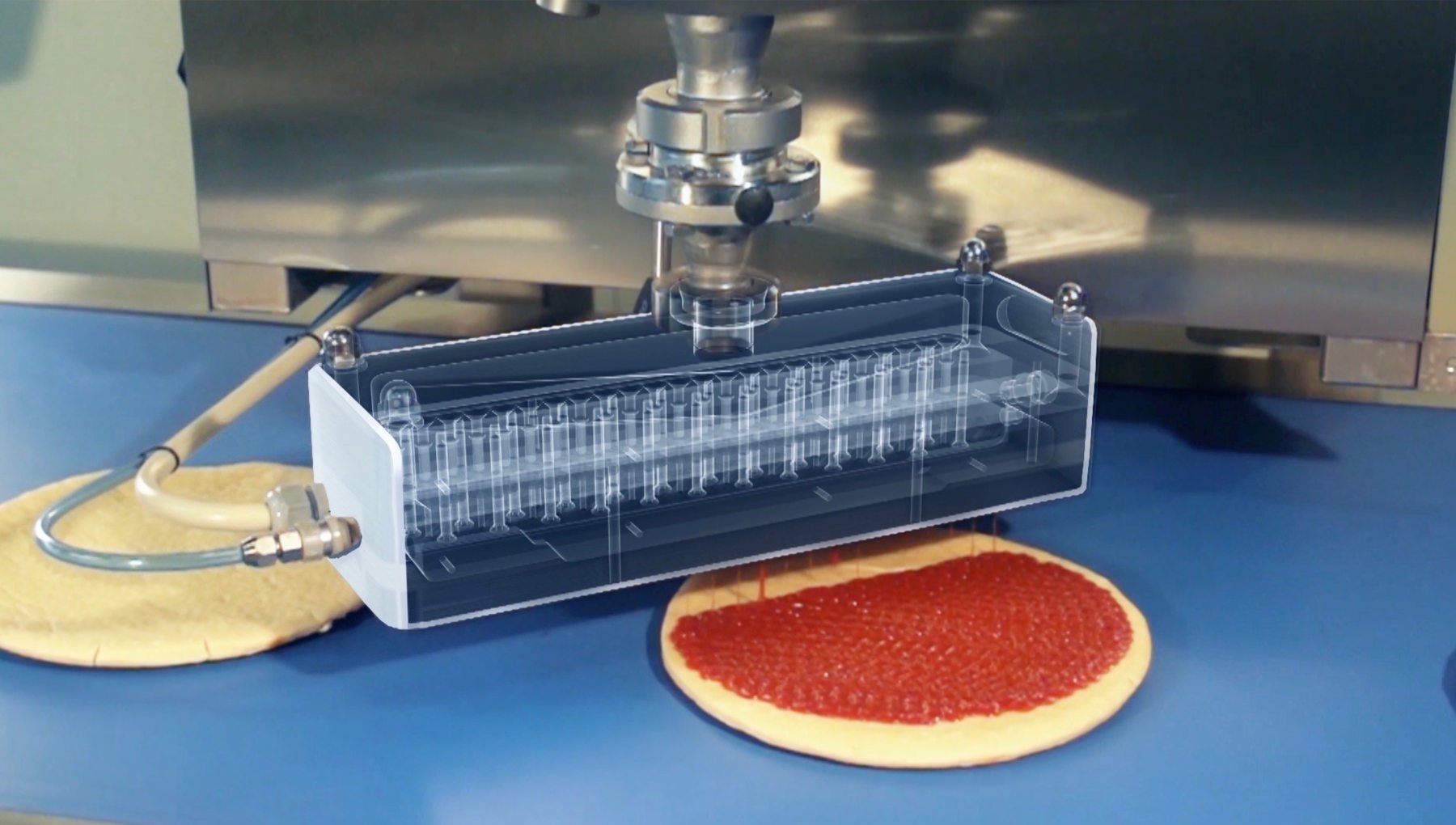

Glaze spraying on pies with the glazing machine

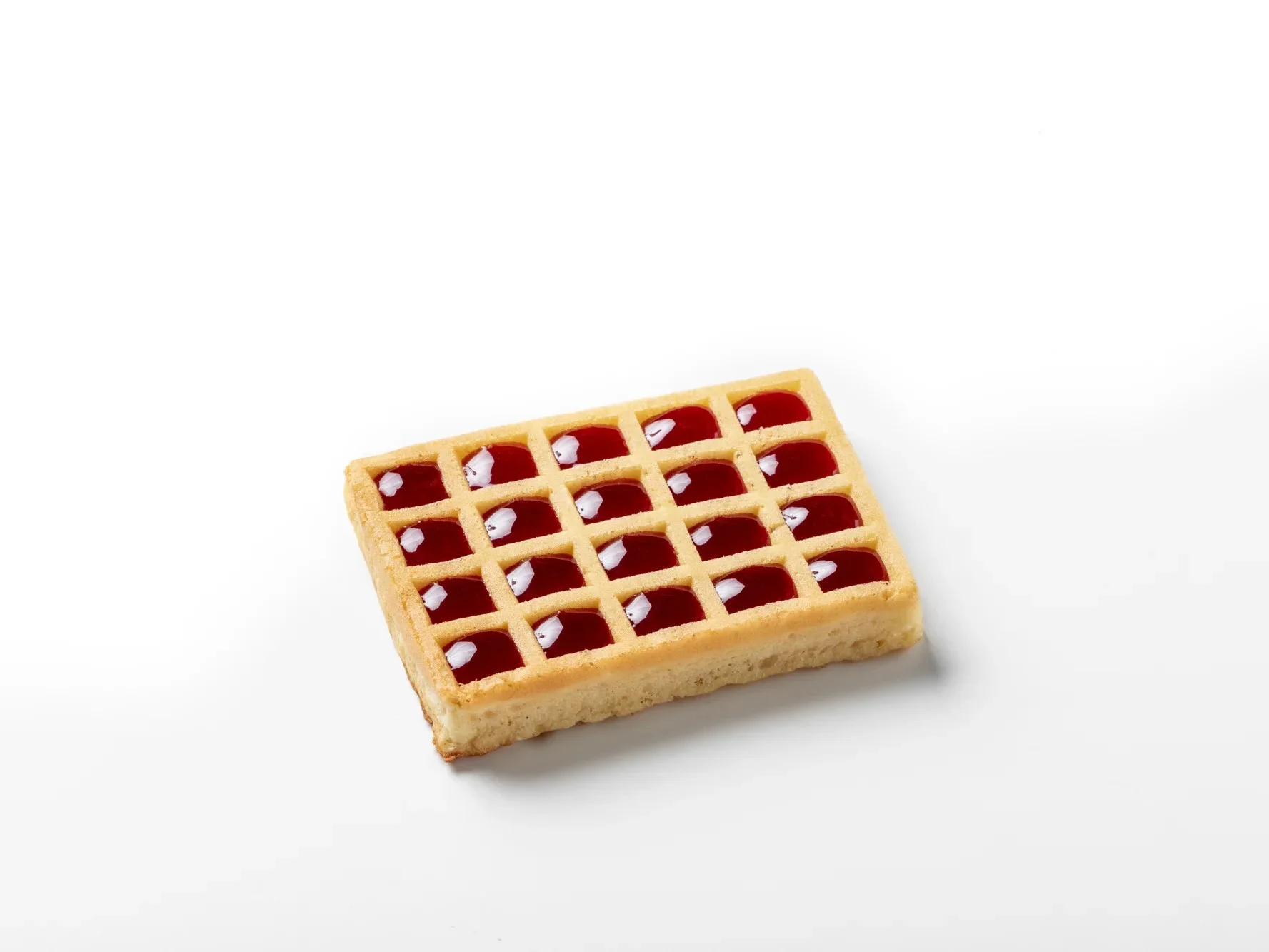

Coating fruit pies with gelatin glaze is traditionally a messy process. That is why Foodjet has developed a glazing machine that can target the pies without spilling a drop of glaze outside the product. On top of that, the glaze is only heated right before it is deposited, so material quality isn't affected and energy use is highly efficient. Our glazing depositors can glaze the pies in only one pass, instead of twice with a conventional spray nozzle.

Do you already have a particular glaze spraying application in mind? Or would you like to consult one of our specialists? Then contact us without any obligation. We will gladly tell you about all the advantages of our glazing machines.

Clean glaze depositing process

The nozzles used by FoodJet are positioned close above the surface of the product. The array of nozzles are only activated where the product passes underneath, so the material is applied only on top of the product. No glaze falls next to the product on the conveyor. This is how the glazing machine saves material and keeps your process clean.

Higher quality material

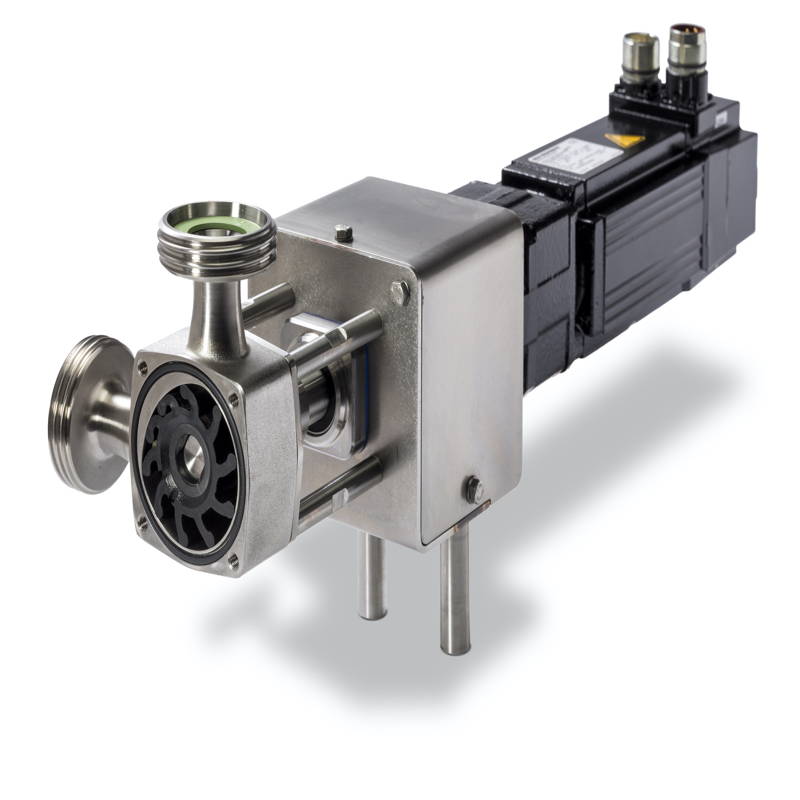

The glaze is only heated to high temperatures right before the material is deposited. This will guarantee a better quality of the glaze. It will not deteriorate in the holding tank where it usually is kept for a long time at a high temperature. FoodJet offers a supply system that controls the full process while making sure the glaze has the perfect temperature and best quality when it is applied.

Saving energy costs

Thanks to the smart FoodJet supply system, you do not have to maintain the high temperatures in the holding tank all day long. The energy costs for keeping the material warm can be considerable. FoodJet only heats up the glaze that is needed in the process, when it is needed in the process.

Less waste than traditional glazing machines

At the end of the day, what material remains in the tank has to be disposed. It cannot be recovered for a next production run as you cannot cool it down. In the FoodJet supply process, the material only reaches high temperatures before depositing. So the glaze that remains in the tank can be used at a later stage.

Adding to that, the material is deposited onto the product, not onto the conveyor or surrounding environment. This is a major cost saving.

Other interesting applications

The depositing solutions of FoodJet are always tailor-made to suit the needs and wishes of your production process. This means that no machine is exactly the same! This allows us to manufacture depositing solutions for a wide range of depositing materials. Take a look at our similar applications:

Typical system configuration of a glazing machine

A glazing machine could comprise the following:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!