Pizza making machinery taken to the next level

For mass food producers seeking to upgrade their pizza production processes, FoodJet's advanced pizza making machinery offers a game-changing solution. Specializing in high-precision depositing technology, Foodjet equipment ensures accurate and consistent application of pizza sauces, cheese toppings, and other ingredients.

Revolutionizing pizza production with advanced pizza making machinery

The automated systems streamline the pizza making process, boosting production efficiency and reducing waste. With Foodjet’s solutions, you can achieve uniform distribution across large volumes of pizzas, improving product quality and consistency. The pizza making machinery and technology also supports customizable recipes, allowing for flexibility in production without sacrificing precision.

Explore more about our pizza-making machinery and how it can elevate your production.

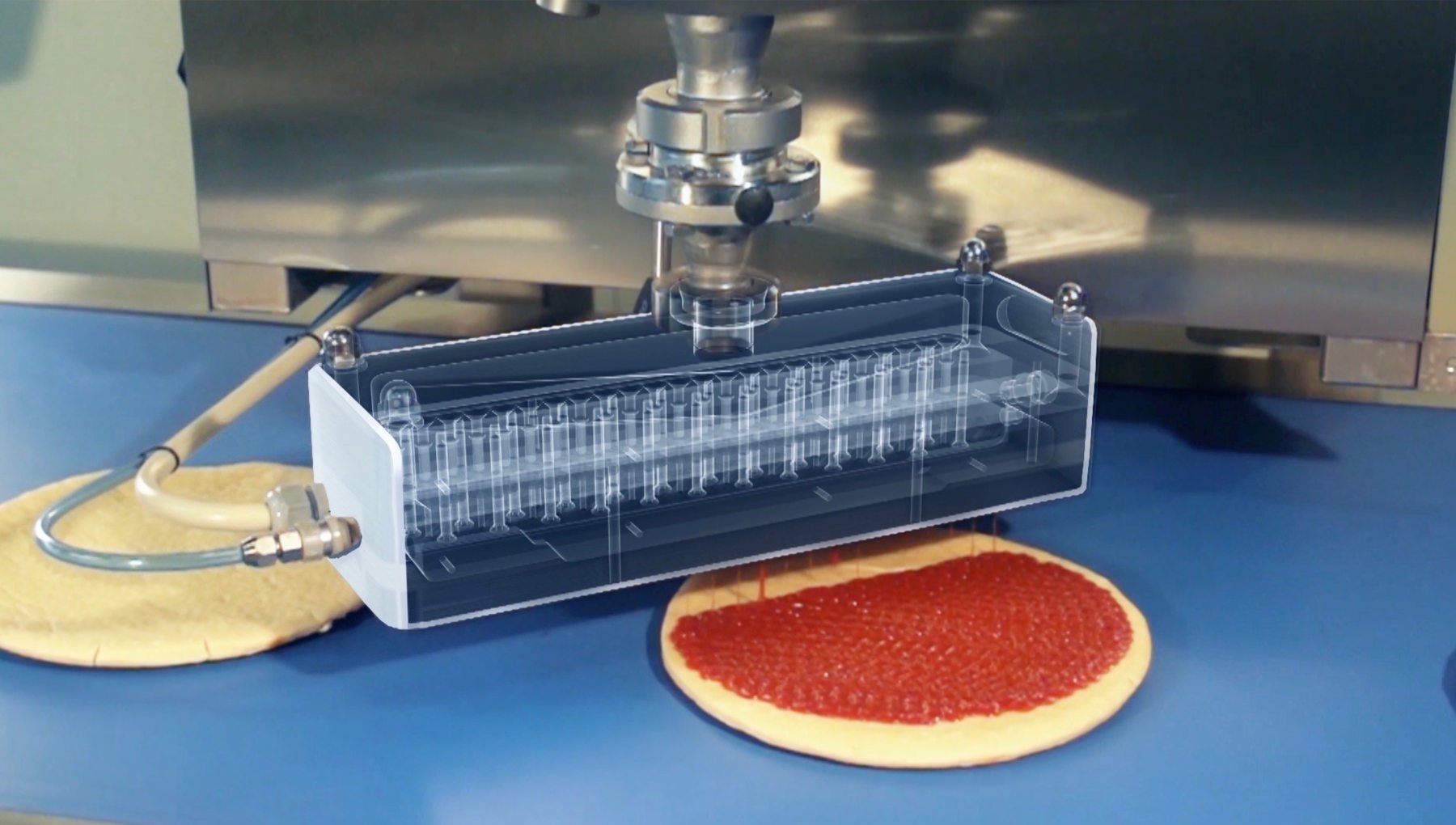

Our pizza making machinery in action

A leading French pizza producer is now utilizing FoodJet's latest Moveable Depositor Large (MDL), a state-of-the-art pizza factory machine, designed to enhance the pizza-making process.

Their previous equipment struggled with their tomato sauce, prompting the switch to this advanced pizza machine. The MDL’s software-driven controls eliminate the need for mechanical adjustments, ensuring precision in pizza sauce and cheese application. Equipped with large-diameter nozzles, this machine handles various sauces with ease, making it a must-have in modern pizza factories.

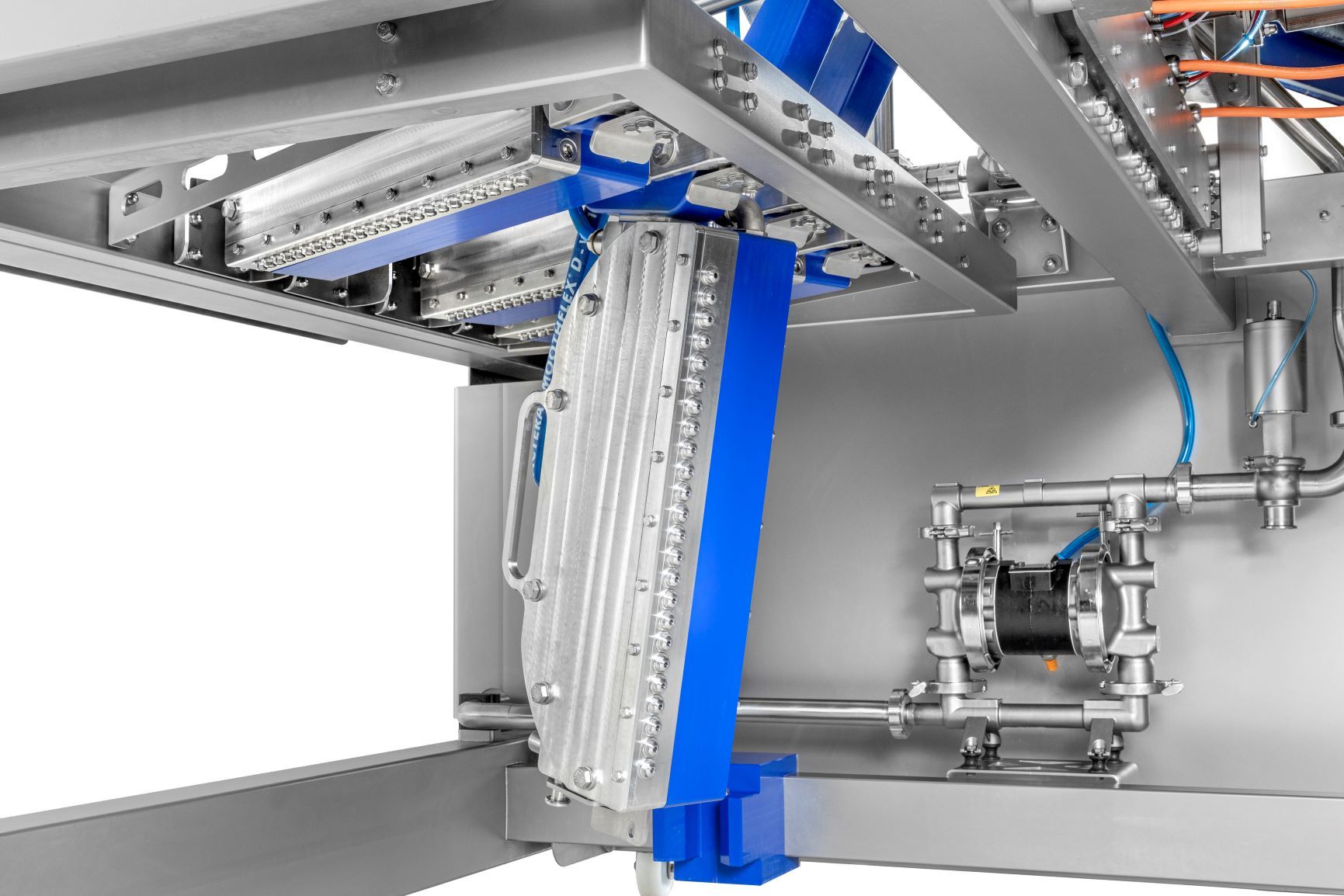

Benefits of the MDL

Foodjet’s MDL (Mobile Depositor Large) transforms pizza production with its exceptional depositing quality, ensuring precise and uniform topping application. Among our depositors, the MDL has the highest visual depositing quality.

It integrates seamlessly into existing pizza making machinery lines, offering intuitive controls and minimal downtime for unmatched operational efficiency.

The MDL handles high volumes reliably, boosting production capacity and reducing maintenance needs. Its versatility supports diverse recipes and innovative topping combinations, making it ideal for adapting to market trends.

Overall, the MDL combines superior quality, efficiency, and flexibility, enhancing any pizza production operation.

Looking for a similar application?

The pizza factory machines of FoodJet are always tailor-made to suit the needs and wishes of your production process. This means that no machine is exactly the same. This allows us to manufacture depositing solutions for a wide range of depositing materials. Take a look at our similar applications:

No mechanical change-overs

The proprietary Free Form Pattern Generator (FFPG) software lets the user choose the exact settings for each product type and shape:

- How big the sauce-free edge should be

- How much sauce should be applied

- How the depositor should respond to off-spec products

- ... and much more

All this can be done without making any mechanical changes. It is all software-based, so customer-specific requests can be implemented if required.

Large diameter nozzles

Our pizza-making machinery is renowned for its innovation in the food industry. Typically FoodJet's pizza making machinery is equipped with large diameter pinch valves. These valves are particularly suitable for handling pizza sauce as they are less sensitive to inclusions in the material.

Besides that, there are no moving parts which contributes to lower maintenance costs and easier operations.

About FoodJet

FoodJet is the leading company in precision depositing of liquid foodstuff. Since the turn of the century we offer our services to the bakery and confectionary industry. We are always one step ahead when it comes to helping our clients solve their depositing challenges. Supplying our systems to the leading food processors in the world, more and more companies trust FoodJet with improving their product quality and decreasing their cost of production.

Would like to receive our articles and updates?

Sign up for the FoodJet Newsletter.