Cheese depositing on buns

Industrial production of cheese buns is hard to do. It is a costly part of many production lines. Many producers have been looking for alternatives to the traditional cheese waterfall systems. FoodJet's cheese depositors offer a solution for significant cost savings.

What goes wrong with traditional machines?

Many production lines presently use a water spraying system before a cheese waterfall. The idea is to make the shredded cheese stick better to the product because of the water. Nevertheless, you see a lot of things that go wrong:

- Cheese does not stick to the water adhesive and falls off

- In many cases, more than 50% of the cheese is returned by a carousel system

- Material falls off in the freezing tunnel, causing major cleaning issues

- Products do not look nice in the packaging as most of the cheese has already fallen off before

Cheese depositor alternative

FoodJet offers a liquid cheese alternative that has proven to be a major leap forward in many aspects. You replace your water spraying system with a system that applies liquid cheese. This cheese will function as an adhesive for the following waterfall system. This investment creates a fantastic ROI:

- All cheese that falls on your products will remain there. So you can significantly reduce the number of cheese flakes.

- Cleaning costs downstream are simplified tremendously.

- Client appreciation of the final product has increased

Want to learn more about the possibilities for your production process?

Any conveying system

It does not matter if your products are on a tray or a conveyor belt. FoodJet can handle many different conveying systems. As we deposit all material on the product, the pollution of the production line downstream is neglectable.

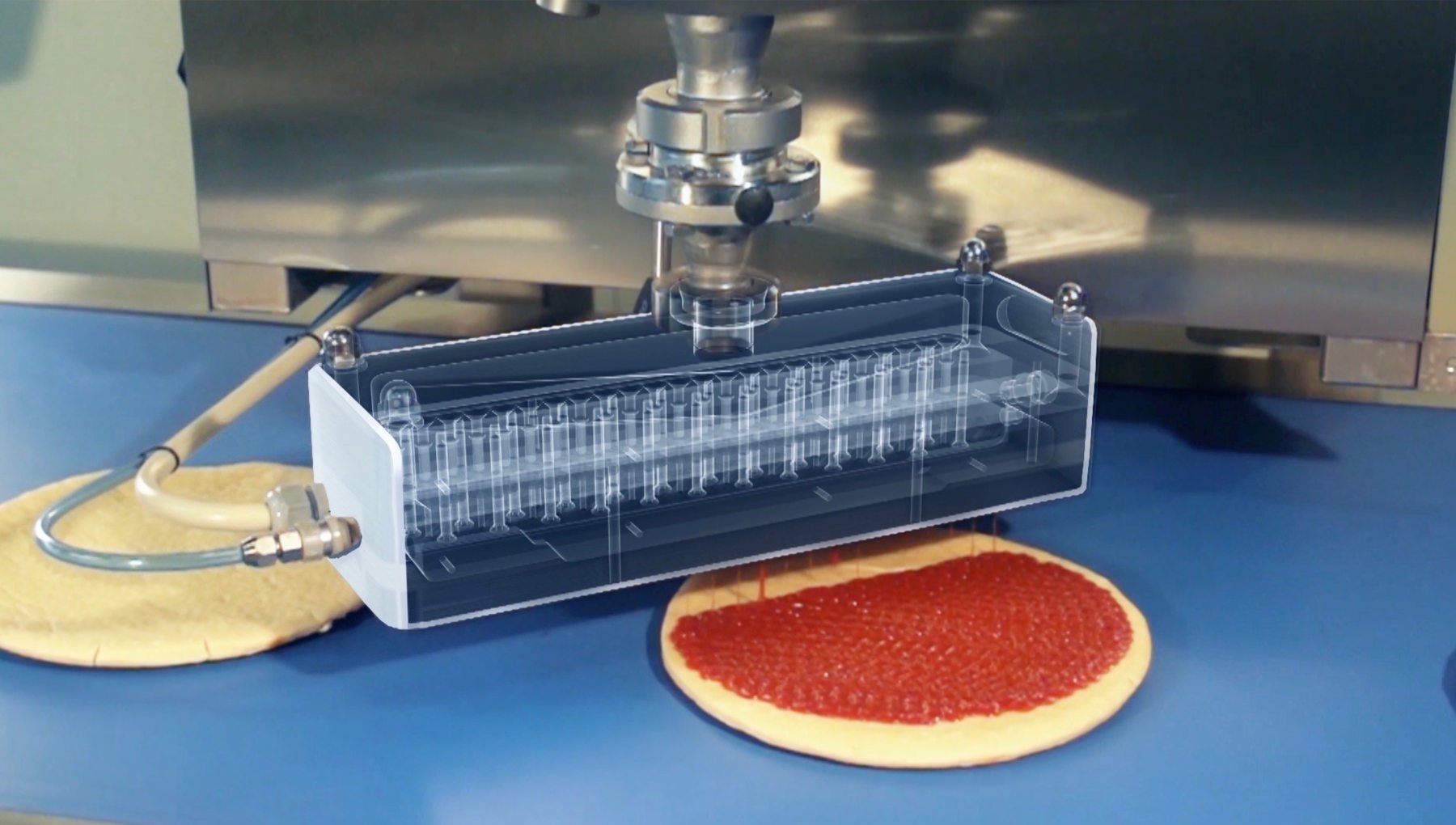

Cheese application video

The following video was shot in our test lab. It shows you the necessary steps of how a typical FoodJet cheese depositor process could look like:

What other products to deposit cheese on?

The FoodJet depositing technology stands out because of its flexibility. It is particularly suitable for applying cheese to products that are not aligned, products that have odd shapes, or maybe even product flows with multiple shapes at the same time. The FoodJet vision system will capture it all. Anything is possible. Just reach out to us and schedule a demo in our test lab.

Other applications

FoodJet's depositing solutions are custom-designed to align with the specific requirements and preferences of your production process. This ensures that each machine is unique. This flexibility enables us to create depositing solutions for a diverse array of materials. Explore some of our other applications:

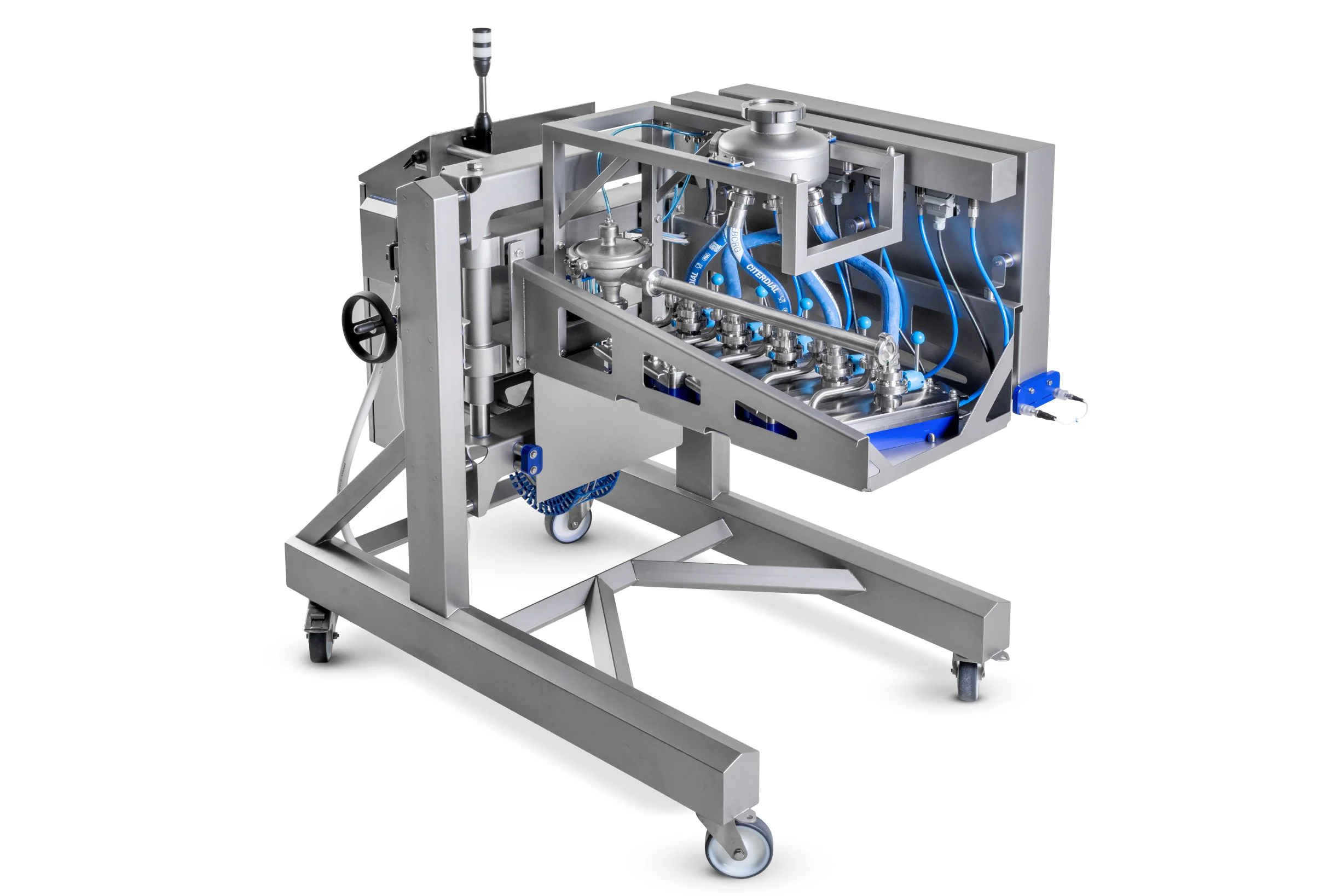

Typical system configuration

If you would like to know what a typical cheese depositor system looks like, just check out the following setup:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!