Produce Jaffa Cake with our pectin jam depositor

The challenge of depositing pectin jam

Pectin jam is commonly seen on various products, such as cookies, cakes or waffles. One particular example of the application of pectin jam are Jaffa cakes.

Nevertheless, depositing pectin jam has a range of challenges for producers.

- Controlling the temperature in the whole process

- Blocked nozzles during a production stop

- The right balance in viscosity

In the production of Jaffa Cakes or other sponge-type cakes, there is an additional range of issues that greatly impact the quality, cost, and looks of the product. Nevertheless, these issues are solved with the depositing slutions of FoodJet. Let us tell you how we achieve this.

Smaller batch quantities

It is no longer necessary to keep large quantities of material in a holding tank before depositing. FoodJet only circulates a small quantity of material that is required for immediate depositing. The majority of the material can be kept in a separate tank. In case of a more extended stop, you only lose the small amount of material in the circulation. The decay of material is minimised.

As this circulation contains less material, you can easily produce small batch sizes. Switching quickly from one recipe to another is within reach.

Lower energy consumption

There is no need anymore to maintain the holding tank at high temperatures all day long. The energy savings this will bring will add up quickly over the course of a year.

Our test showed better results at lower depositing temperatures. The viscosity went up, and the required cooling time went down. Again, this will amount to lower energy consumption in the cooling tunnel.

Improved quality

FoodJet depositors can compensate for any misalignment of products. Or rather, it does not matter where products are positioned on the conveyor. The vision system will send the exact position of each product to the depositing heads. Therefore each deposit of jam will be placed in the exact center of the product.

It is even possible to use the depositor as a quality check for your production. If products fall out of certain quality specifications, the system will not apply any material to the product. This will make it visually easy to detect out-of-spec products and remove them from the product flow.

Less waste

Sponge-type products are difficult to produce. There is always a possibility that the bases are not within size specifications. The alignment process is seriously disrupted if products the fail the criteria block the channels going to the traditional depositors. As FoodJet does not require any alignment, the cause for this possible waste-producing step is removed.

Even alignment steps sometimes fail to put the products in the correct position. The result is that jam is deposited off-center. As a consequence, the material runs off the product onto the belt. Or the material makes the product tilt over. This, again, will result in significant problems during the enrobing step.

Combined with the NPND functionality that the vision system provides, you will not waste any good material on bad products.

Increased production

The depositing step is no longer the bottleneck in the production line.

- Line speed can go up if you do not need to align products.

- The FoodJet depositor can handle higher conveying speeds than traditional depositors.

- Products can fill the conveyor with a smaller pitch.

- Cooling time is reduced.

It is time to release the full potential of your process.

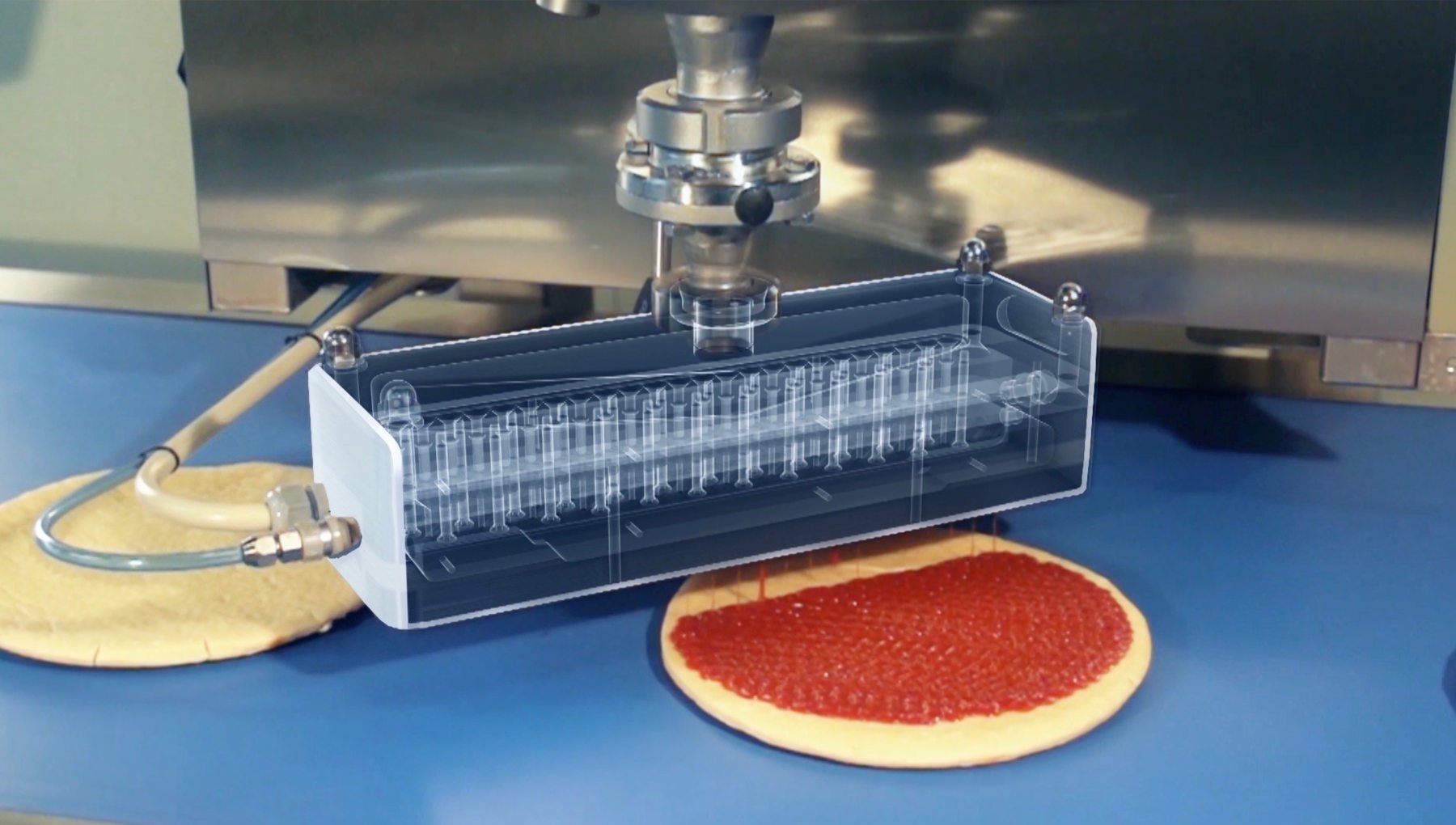

Watch how jam is deposited on jaffa cakes

In the following video, we show you how our depositor places jam onto jaffa cakes in various shapes. Watch the video below and be amazed.

Added value

Finally, a whole new range of products can be created with the same set of equipment. With traditional spot depositors, you can only apply one pile of material to the product. FoodJet depositors can deposit the jam in any shape you like. This opens up the possibility to differentiate products from competitors or for seasonal outings.

Similar relevant information:

About FoodJet:

FoodJet is the leading company in precision depositing of liquid foodstuff. Since the turn of the century we offer our services to the bakery and confectionary industry. We are always one step ahead when it comes to helping our clients solve their depositing challenges. Supplying our systems to the leading food processors in the world, more and more companies trust FoodJet with improving their product quality and decreasing their cost of production.

Would like to receive our articles and updates?

Sign up for the FoodJet Newsletter.