Depositing waffle batter in moulds

Overfilling and visible depositor lines will be a thing of the past when FoodJet starts filling molds with waffle batter in your waffle production line. Top quality products come from precise and even filling. Combined with efficient material and energy use, the choice for Foodjet is evident.

Controlled batter depositing

Using the FoodJet depositing technology in your waffle production, you can control the exact location you apply the batter. You can even vary the amount of material throughout the mould. If you experience that one corner of the mould consistently lacks material, you simply add more material. Or if you notice that batter exits the mould due to surplus-depositing, you can just as easily reduce the deposit locally.

You don't want to spill waffle batter

It matters a lot how and where the batter is deposited:

- You do not want to waste material that is applied next to the mould.

- Batter that does not go into the mould needs to be cleaned.

- Burned batter will cause bad smell and complaints.

Spilling batter in your waffle production line can significantly impact your production costs. By upgrading your waffle production line with FoodJet, you can eliminate this issue and improve efficiency.

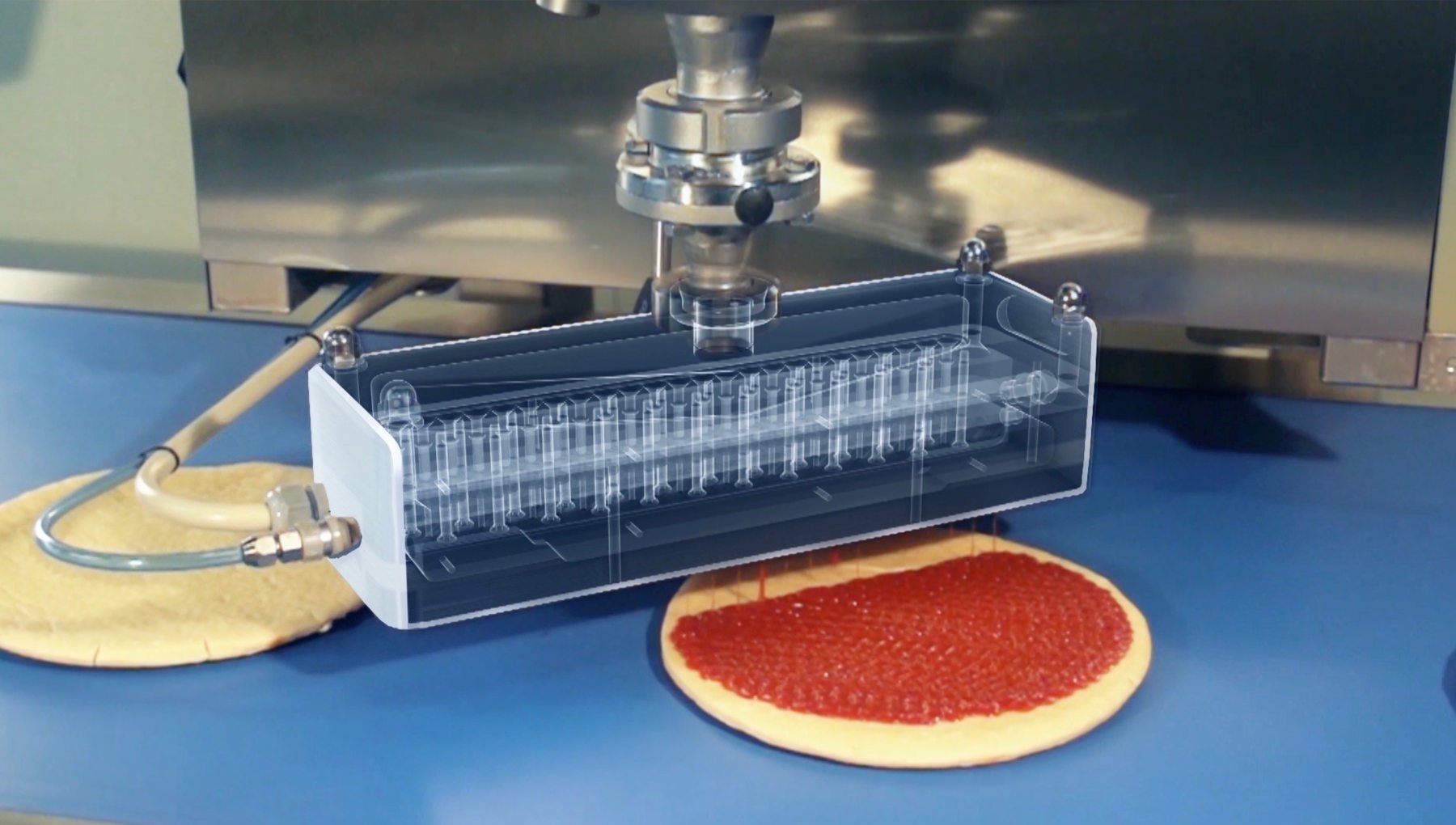

Explore our depositor in action on a waffle production line

In this video, we'll walk you through a practical demonstration of our depositor solution depositing waffle batter directly into the mold. See how our technology is unique compared to traditional waffle machine manufacturers and how it can make a difference in your waffle production line.

Multiple colour depositing

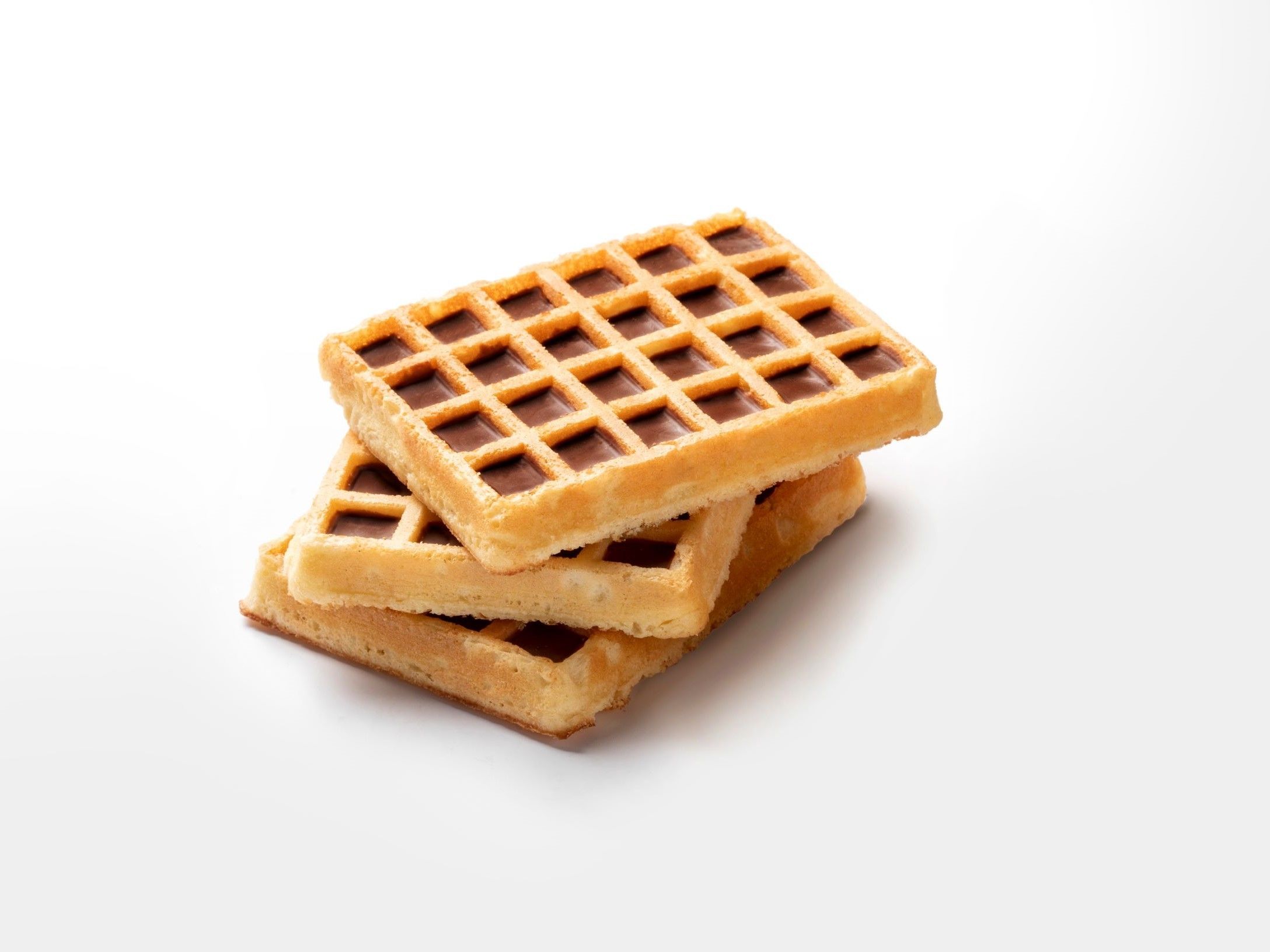

Are you looking for a way to create new and unique products? How about depositing multiple colors of batter in the same mould? Each drop of batter can be deposited according to a pre-designed pattern. This gives you the possibility to create designs with two colors that look fantastic. With the FoodJet Designer Studio it is easy to create the products that sell.

Odd shaped moulds

You do not have to produce square-shaped products only anymore. If you are no longer limited by your depositor, you can apply batter in any shape you are looking for. Think of all the new products you can create.

More similar applications

FoodJet specializes in tailoring depositing solutions to match the specific waffle production line needs and desires. As a result, each machine is one-of-a-kind! As a waffle machine manufacturer, this enables us to create depositing solutions for a diverse range of materials. Explore our parallel applications:

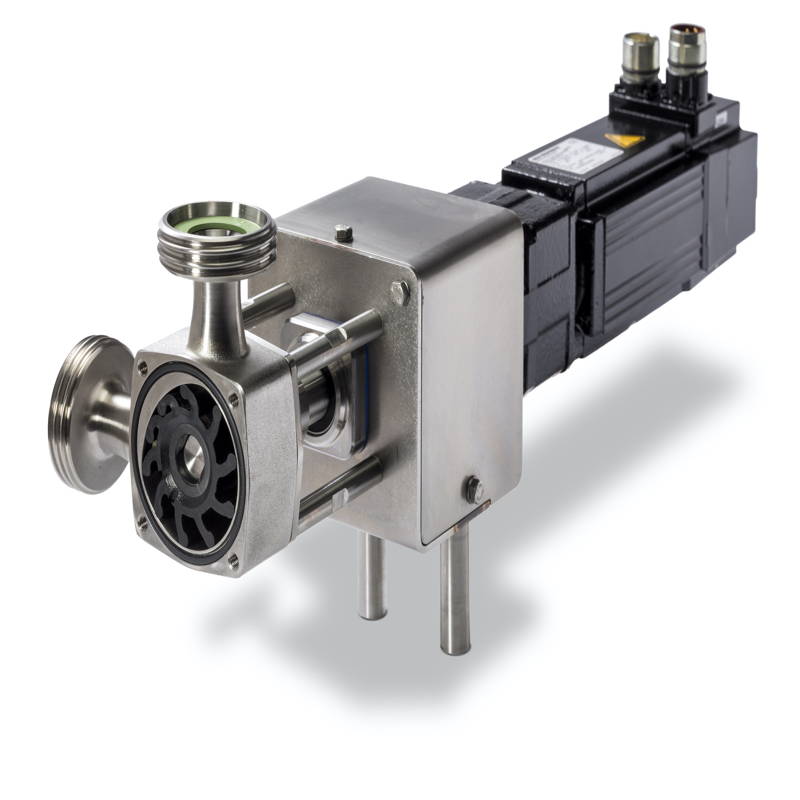

Typical waffle production system configuration

As a leading waffle machine manufacturer, FoodJet provides advanced equipment for your production line. A typical setup with FoodJet's waffle depositor might include the following components:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!