Tiger paste depositing

Tiger paste provides the perfect crunchy crust

Tiger paste, used to make tiger bread, is a type of bread characterized by its crackly, caramelized crust that resembles a tiger's stripes. Some call it tiger paste, others call it tiger wash, Dutch crust or even Giraffe bread. The crust is made by coating the bread with a paste of rice flour, sugar, and yeast before baking. The tiger bread itself is typically a soft, fluffy white bread. The rice paste that imparts the tiger bread's characteristic flavour dries and cracks during the baking process.

The history of tiger paste

Tiger bread has an interesting origin story. It was first created in the Netherlands by a baker who wanted to make his bread stand out among the competition. The unique crust was inspired by the markings on a tiger's fur, hence the name. The bread became popular in the UK when it was introduced by a supermarket chain in the early 2000s, and it has since gained a following in other countries as well. Despite its popularity, the paste used to make the crust has faced controversy due to the use of certain ingredients that some people may be allergic to.

For sure, tiger paste is one of the products that welcomes a growing worldwide popularity. More and more producers discover the possibilities for creating exciting new products using this material. Besides tiger bread, disruptive new product combinations like tiger paste with croissants, paninis, or pretzels are being introduced to the markets.

Ready-to-use tiger paste or mix it yourself?

There are basically two types of tiger paste. Both come in a wide range of different flavors.

- Ready to use tiger paste which comes in buckets that are poured into the buffer tank. There is no further processing required. The FoodJet tiger paste depositor can pump it straight out of the tank onto the products.

- Tiger paste mix comes in a powder form. It has to be mixed with water into a material that is lump-free before it can be processed by the depositor.

The mix in powder form usually is cheaper. It does require equipment, however, to get it ready for production. The ready mix on the other hands, can be used straight away. This comes at a price.

Tiger paste depositor

A tiger paste depositor is an industrial bakery machine used in the bakery industry to apply a tiger paste to the surface of a loaf of bread or other baked goods. The depositor uses a nozzle to dispense the paste evenly and efficiently, resulting in a consistent and attractive finish. This helps to speed up the production process and ensures that each loaf of bread is uniform in appearance.

Are you looking for producers of tiger paste? These are some leading producers of tiger paste mix or ready to apply tiger paste: Ruitenberg Ingredients, Zeelandia, Sonneveld, Ulmerspatz (by CSM Bakery), British Bakels.

Traditional tiger paste application

Unfortunately, it is not so easy to deposit tiger paste with common depositing technologies. Applying the paste manually considerably limits the production speed. And using rollers does not match with modern production requirements of accuracy and positioning. FoodJet's tiger paste depositors help you create the perfect tiger bread.

How to apply tiger paste industrially?

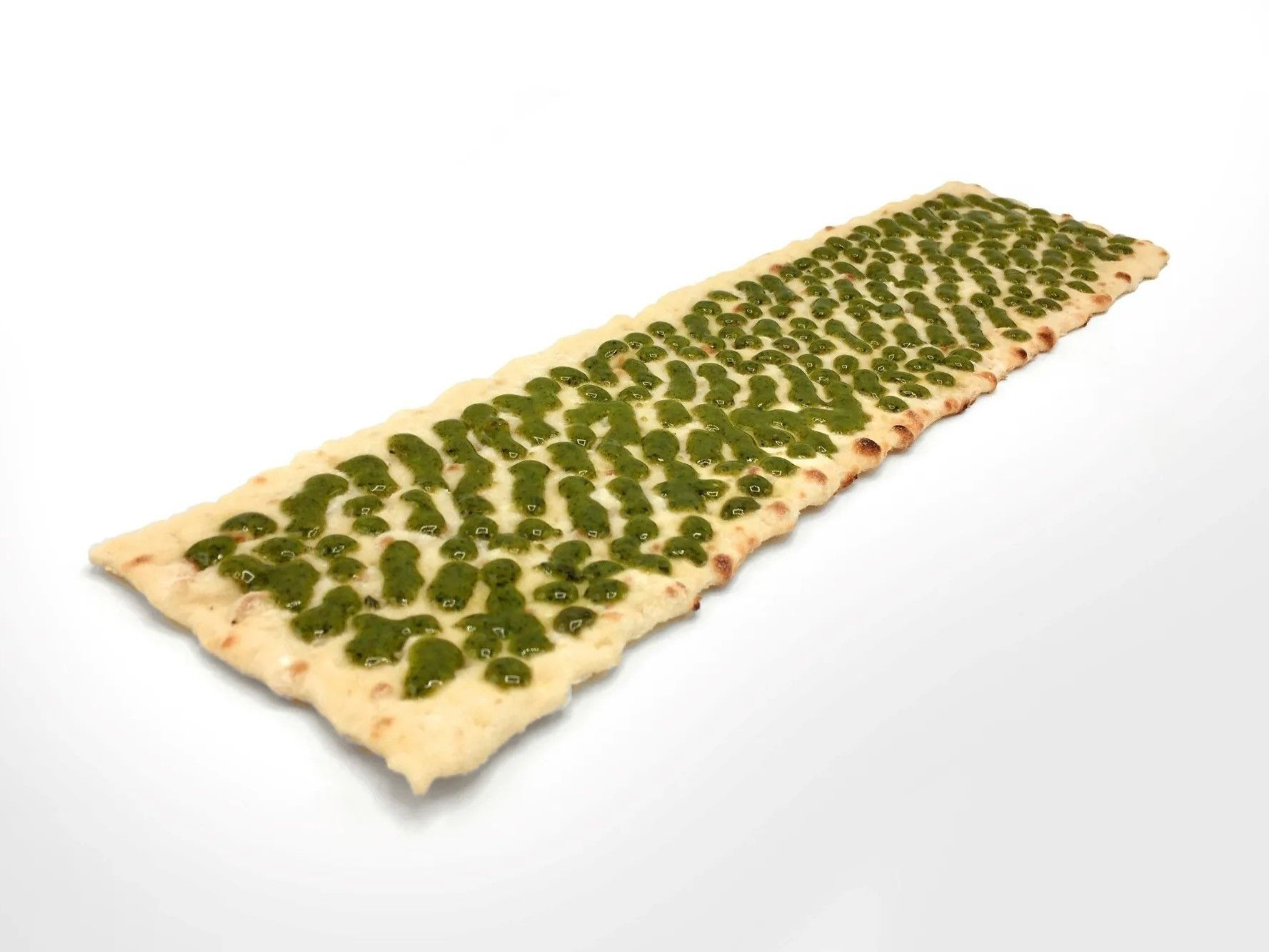

To apply tiger paste industrially, a tiger paste depositor machine is commonly used. The process involves mixing the paste, which typically consists of rice flour, yeast, sugar, salt, and sesame oil, until it becomes a smooth consistency. The paste is then loaded into the depositor machine's hopper, and the bread loaves are placed on a conveyor belt or other transport system that moves them through the machine. The depositor uses a nozzle to dispense the paste evenly onto the surface of the bread, creating the distinctive tiger stripe pattern. The bread is then baked, resulting in a delicious and visually appealing finished product.

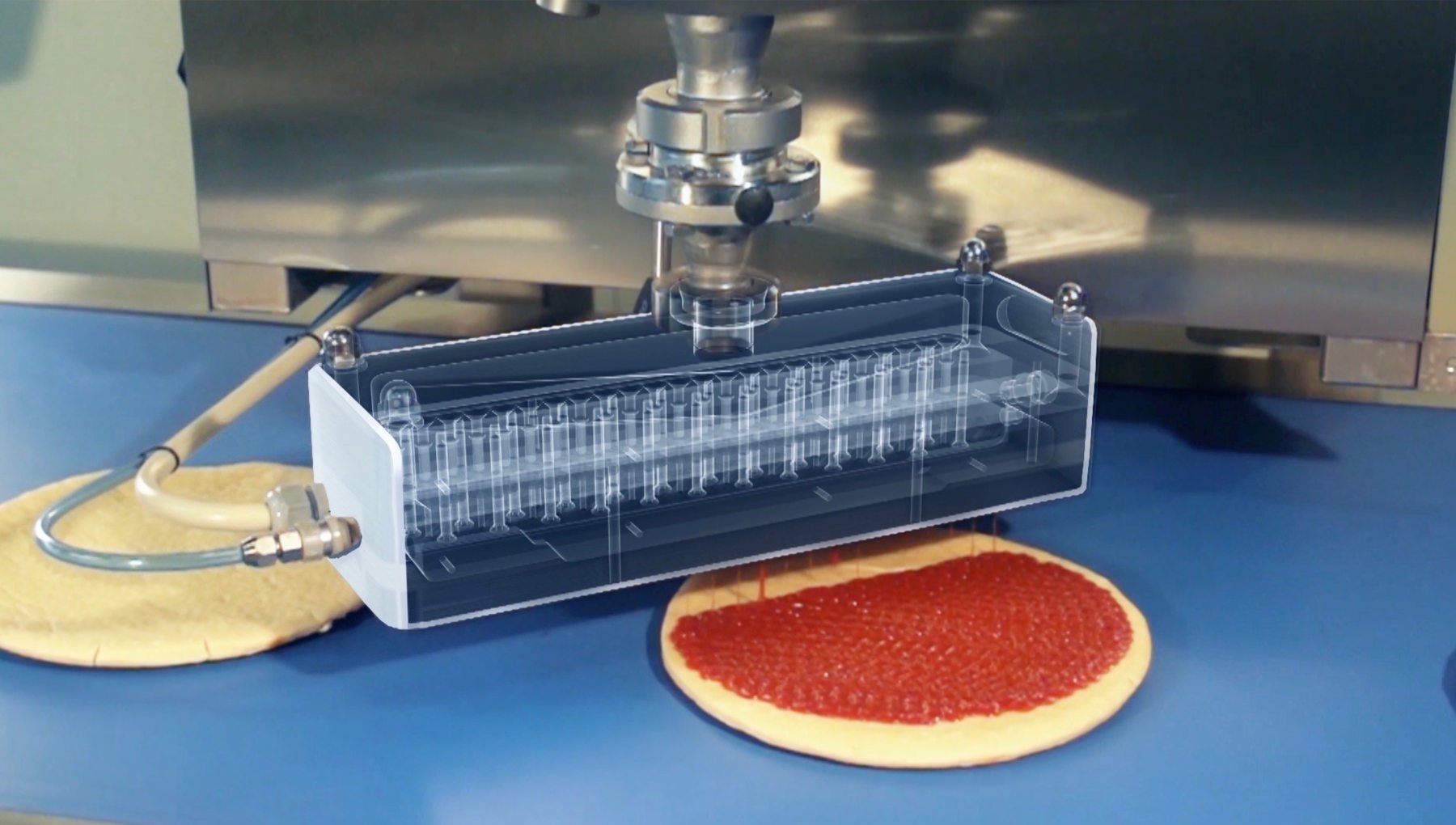

FoodJet uses an array of small nozzles to apply the tiger paste. Depending on the size of the product and the required pattern, nozzles are activated or not. So even if you have an odd shaped product like a croissant, you can still deposit the perfect layer of paste to the product.

How does it work?

- Prepare the tiger paste mix together with warm water in a holding tank or use a ready-to-use paste

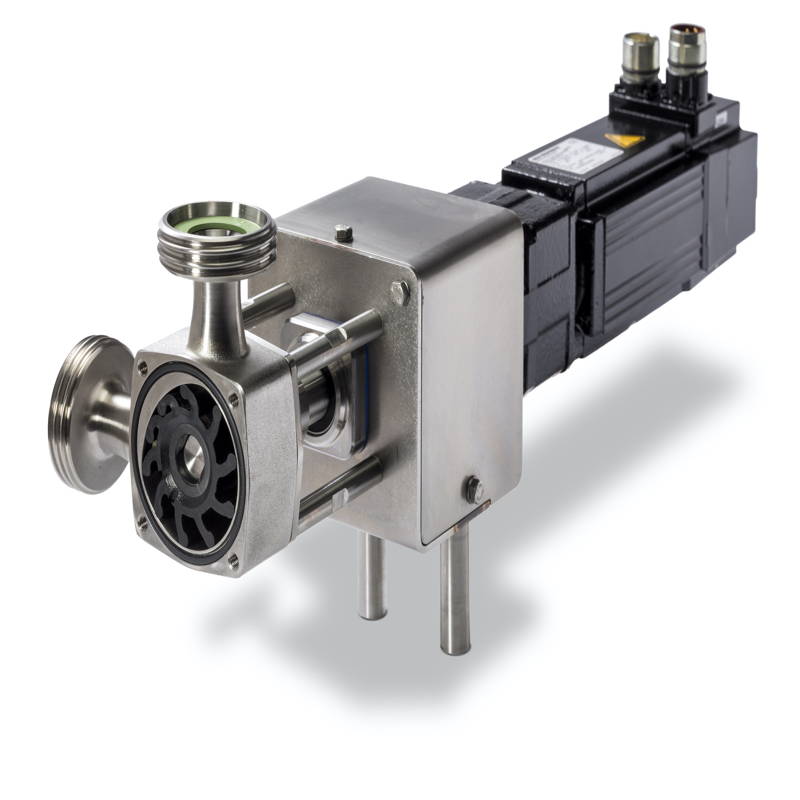

- Pump the material with a constant pressure and flow to the tiger paste depositor

- Load the recipe for the specific product size and material weight from the software

- The depositor detects and identifies the individual products with a camera system

- Each product receives the exact amount of material in the pre-defined position and in the desired layer thickness

Other interesting applications

The depositing solutions of FoodJet are always tailor-made to suit the needs and wishes of your production process. This means that no machine is exactly the same! This allows us to manufacture depositing solutions for a wide range of depositing materials. Take a look at our similar applications:

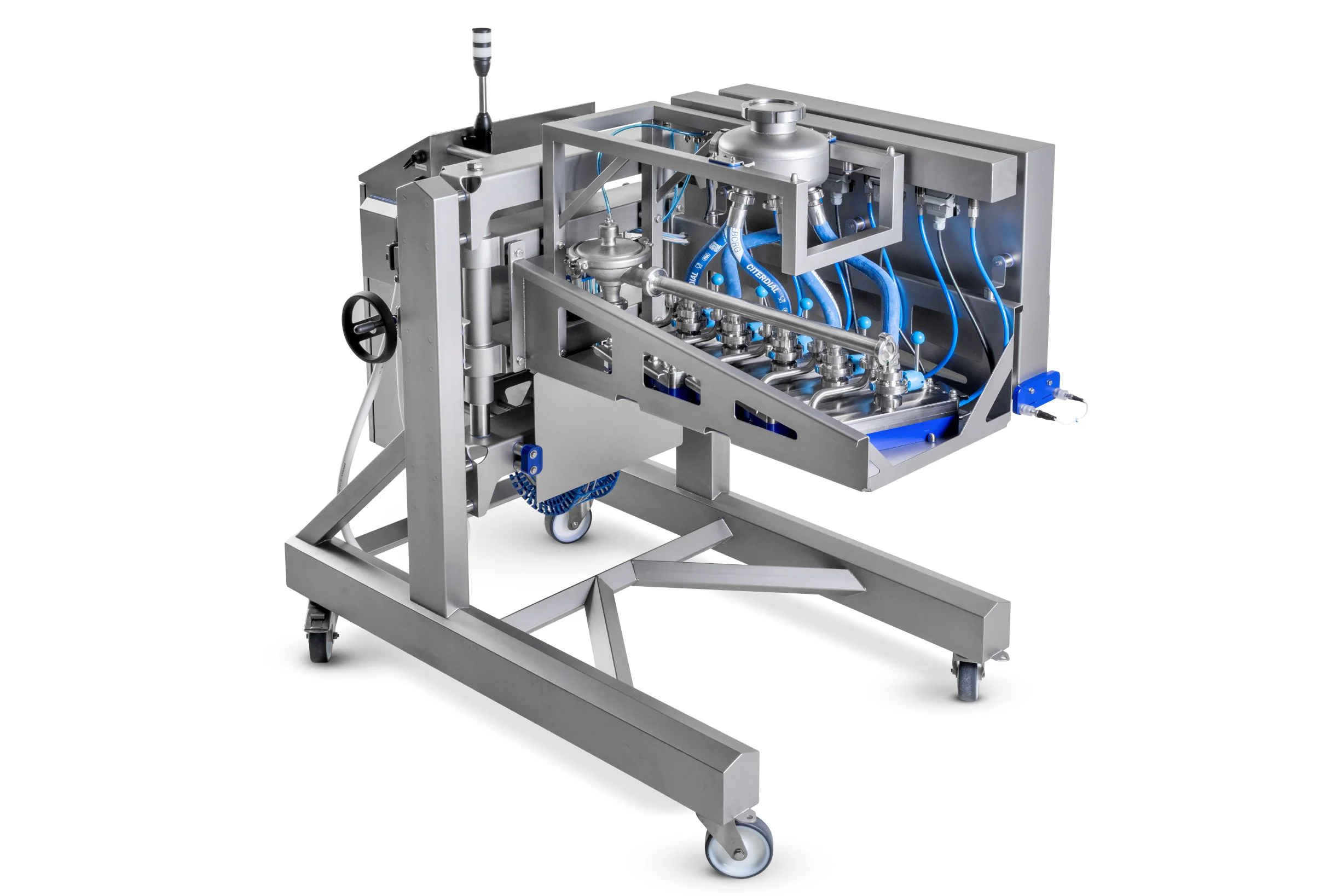

Typical system configuration

We always look for the right product—system combination that matches your production requirements. A tiger paste application could comprise the following:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!