Pizza sauce depositing: the pizza line upgrade

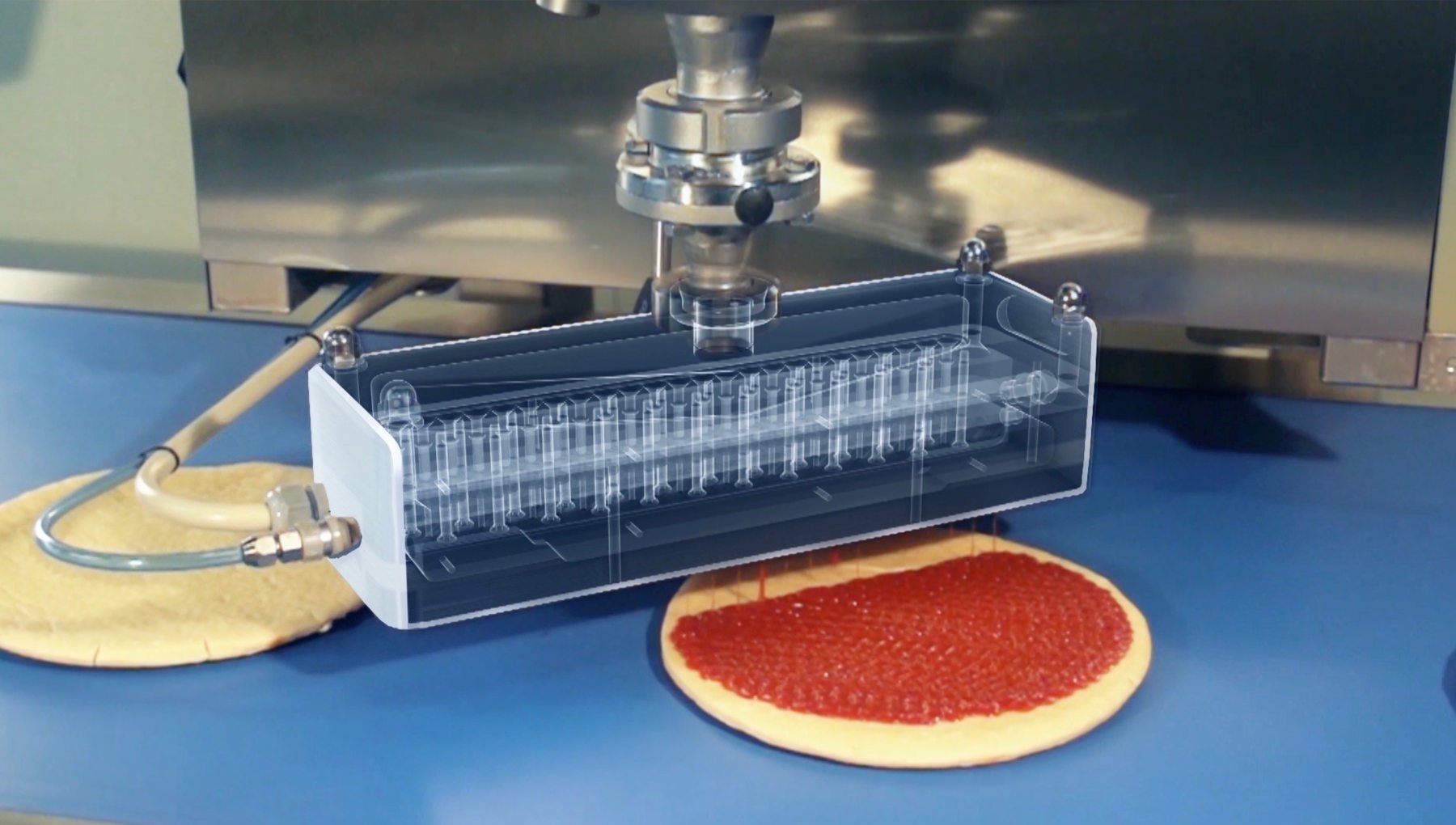

Ever since the origin of pizza in Naples in the 17th century, we have been trying to innovate this delicacy in countless different ways. The demand for smaller, more inconsistently shaped pizza bases in pizza lines is rapidly increasing. Especially with innovations, you want your pizza line to be as efficient as possible. It is difficult to sauce pizzas of different sizes with a regular food depositor. We at FoodJet have found the solution: the pizza sauce depositor.

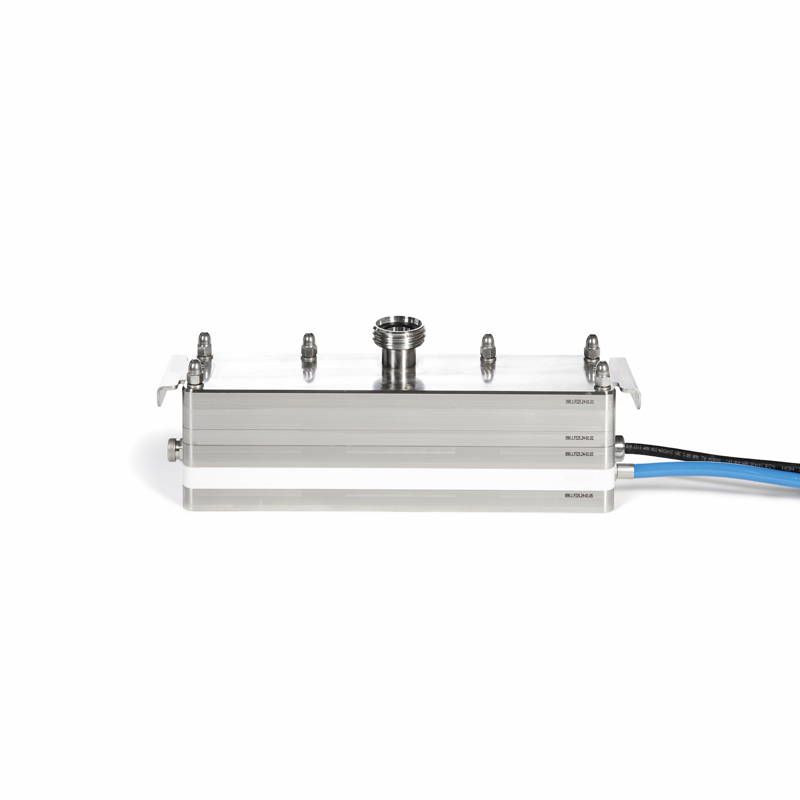

Pizza sauce depositor

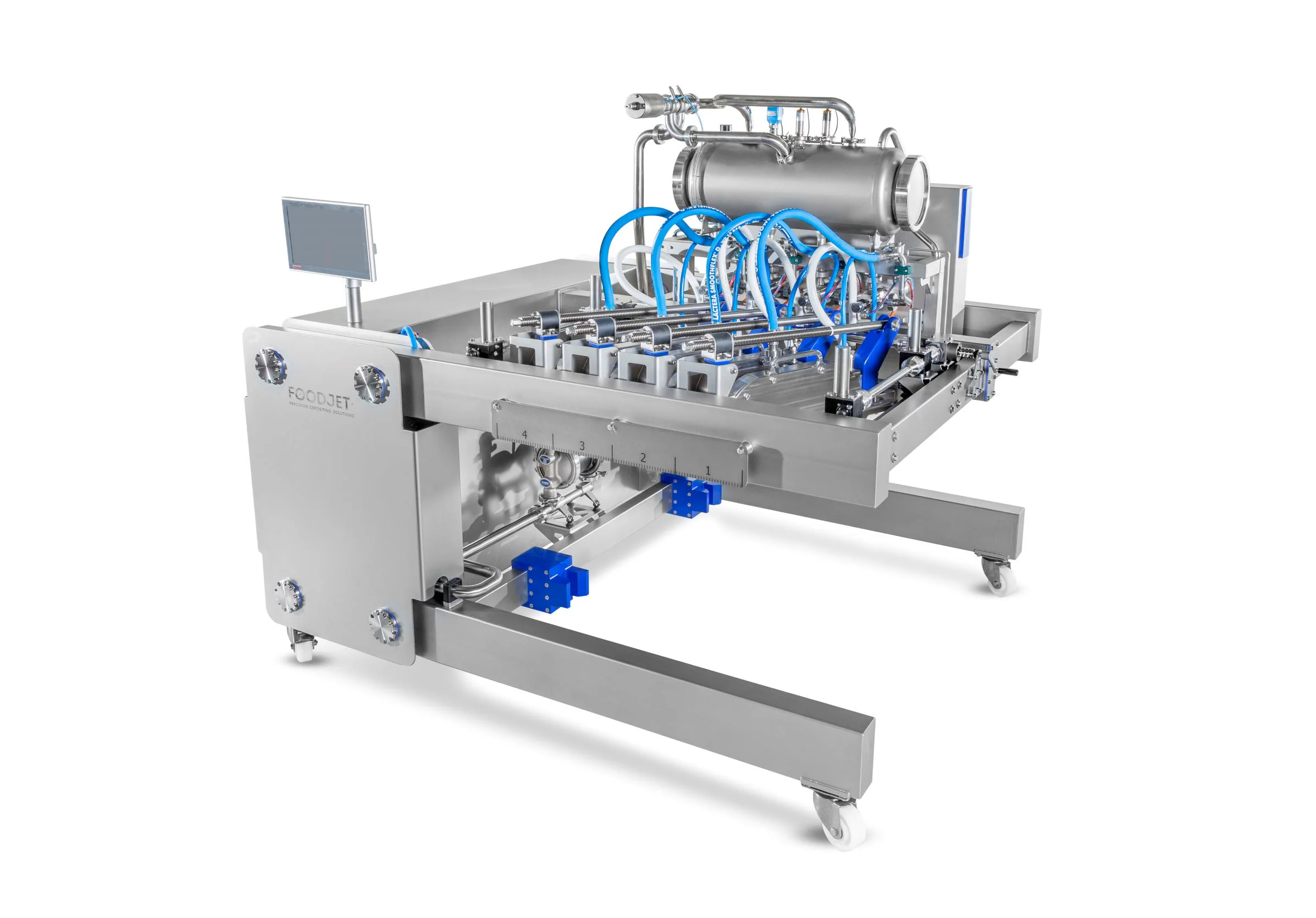

FoodJet depositing solutions knows how to build pizza sauce depositors to improve your pizza line. We eliminate the hassle of using manual labour to produce your pizzas. Other advantages of our pizza sauce depositing machines are:

- High capacity

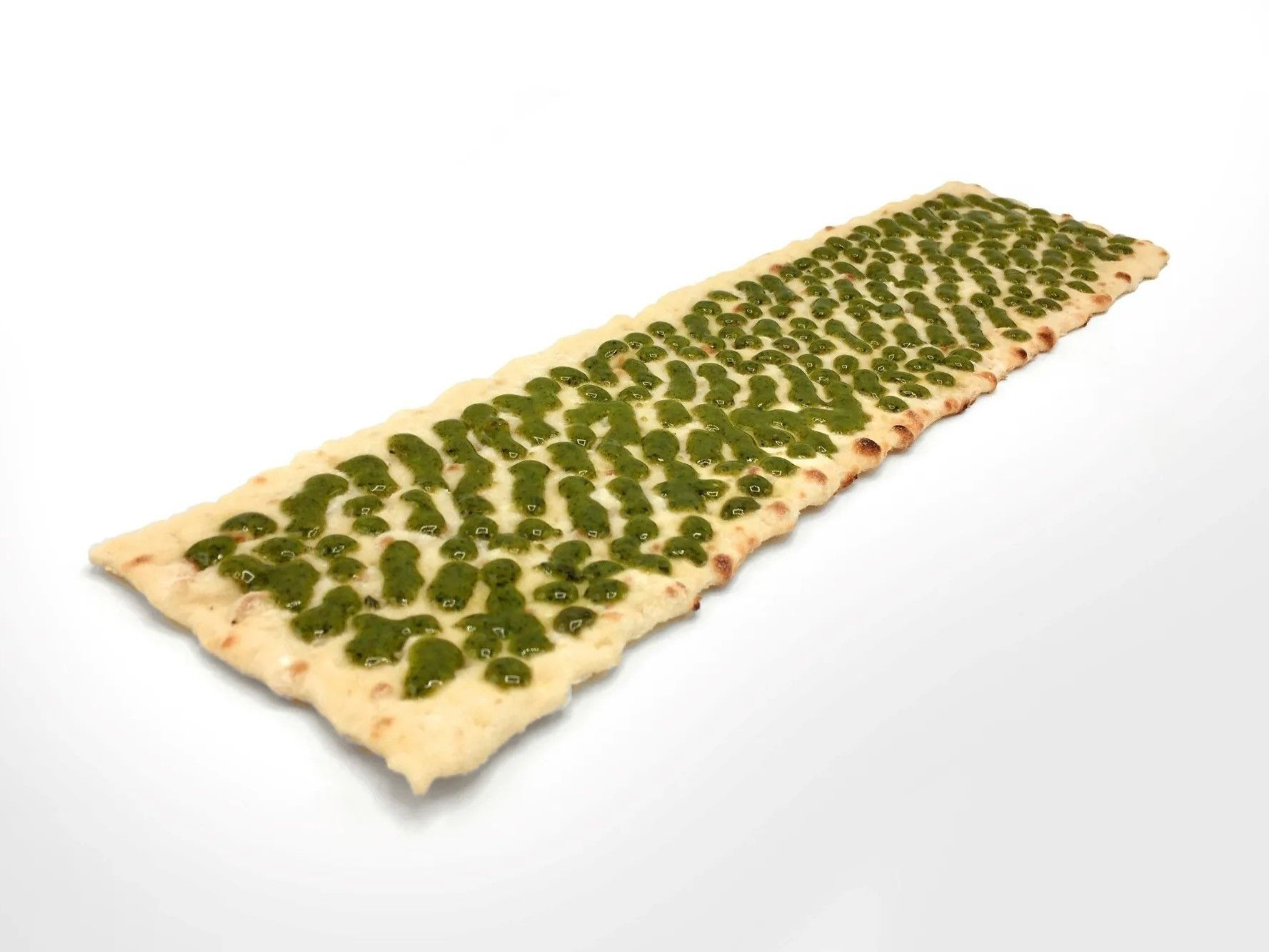

- Completely closed coverage

- Fixed weight with shapes

- Adjustable edge free thanks to the proprietary (FoodJet Free Form Pattern Generator Software)

- Adaptive depositing to product contour

FoodJet depositing solutions creates pizza sauces machines tailored to optimize your pizza production line, eliminating the reliance on manual labor. Our unique depositing technology ensures efficiency and precision in every step of your pizza manufacturing process.

Pizza sauce applicator

If you cover your products with pizza sauce, you face typical challenges like products that differ in shape and product misalignment. FoodJet's pizza sauce applicator was engineered to tackle precisely those problems. It does not use a depositing technology that is fixed to one position. Instead, it can automatically adjust for changing circumstances like pizza bases that have moved on the conveyor.

How to clean an industrial pizza sauce machine?

All of our pizza sauce machines are engineered for industrial environments. You can easily clean the depositor of all pizza topping remains. The software comes with a cleaning program that goes through various cycles. You do not have to dismantle any mechanical parts to successfully get your system ready for the next shift.

Advanced vision technology

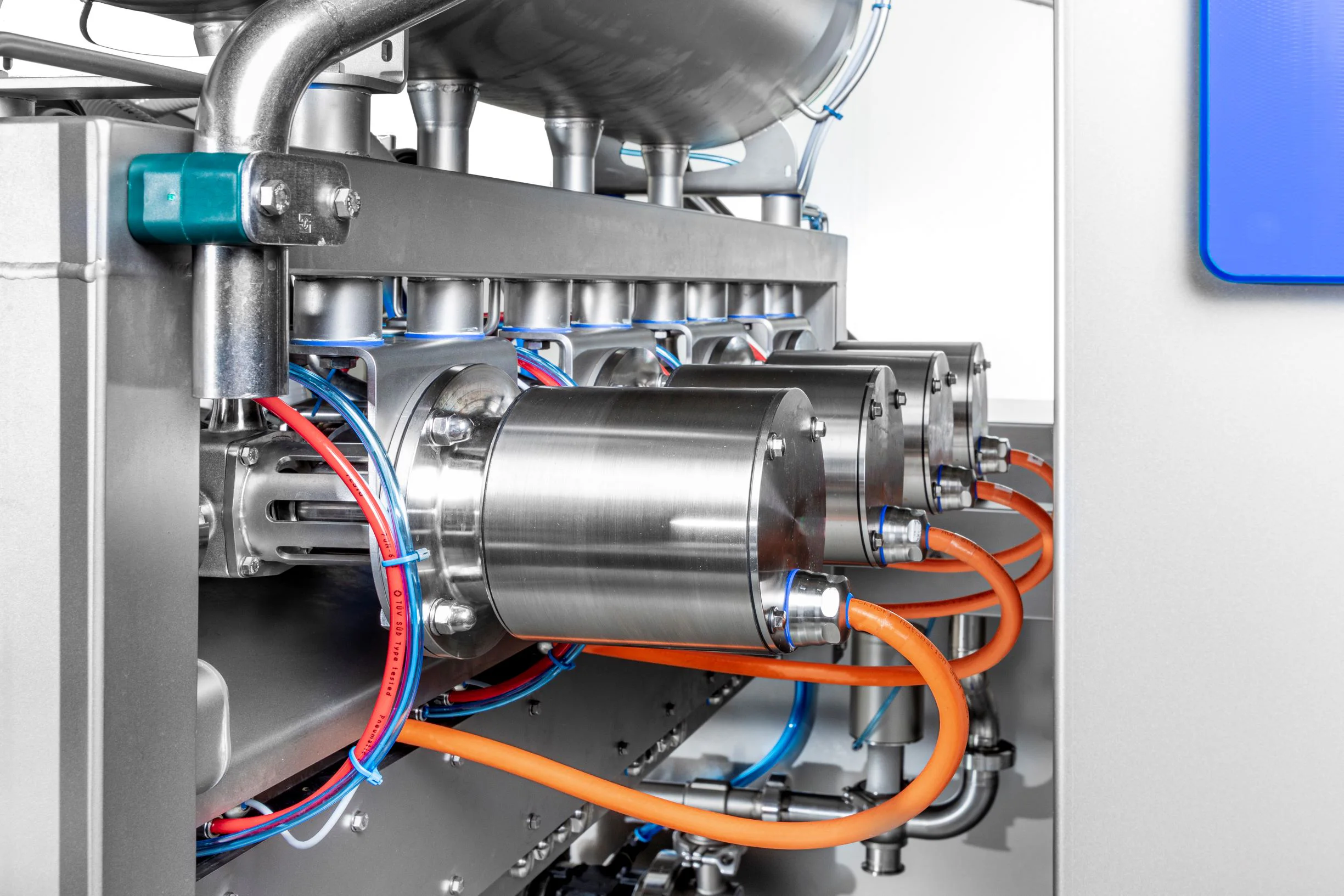

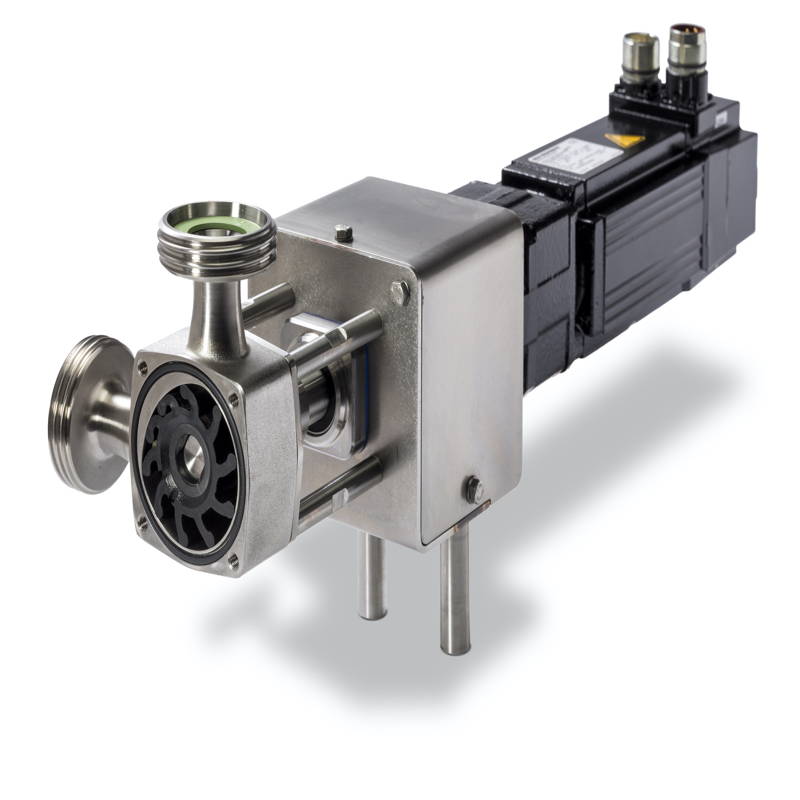

FoodJet uses a camera system to detect and inspect the pizza bases on most of our sauce applicators, inclyding the automatic pizza saucer. Whether you need statistical information on your production throughput, or you want to be in charge of quality, the vision technology helps you improve your production. In combination with the servo driven pumps, weight control is within reach even with differences in pizza crust shape and size. The equipment handles high production speeds even if the pizza sauce has to be applied on pizza crusts that have a different form.

Pizza depositor video

This video gives you a good impression of FoodJet's pizza sauce depositing quality. Let us show you our automatic pizza saucer in action:

FoodJet's depositing solutions

The depositing solutions of FoodJet are always tailor-made to suit the needs and wishes of your production process. This means that no machine is exactly the same! This allows us to manufacture depositing solutions for a wide range of depositing materials. Take a look at our similar applications:

How can we help you?

Do you already have a particular pizza sauce application in mind? Or would you like to consult one of our specialists? Then contact us without any obligation. We will gladly tell you about all the advantages of our machines.

Typical system configuration

Give your pizza production process an upgrade with FoodJet. A pizza sauce applicator could comprise the following:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!