Chocolate topped muffins with our chocolate depositor

A muffin without a topping is only half the product. It is not an easy feat to try to automate a nice broad dosing on the top without the icing running all over one side of the paper. By depositing a perfect circle this is possible! You get the cleanest products and the consumer will have the cleanest fingers!

What does FoodJet do differently?

Of course, there are already solutions for your industrial muffin production line out there that can deposit chocolate or such on muffins. These are commonly one-shot depositors that apply a large amount of material in one position. You cannot control how the material will spread over the product.

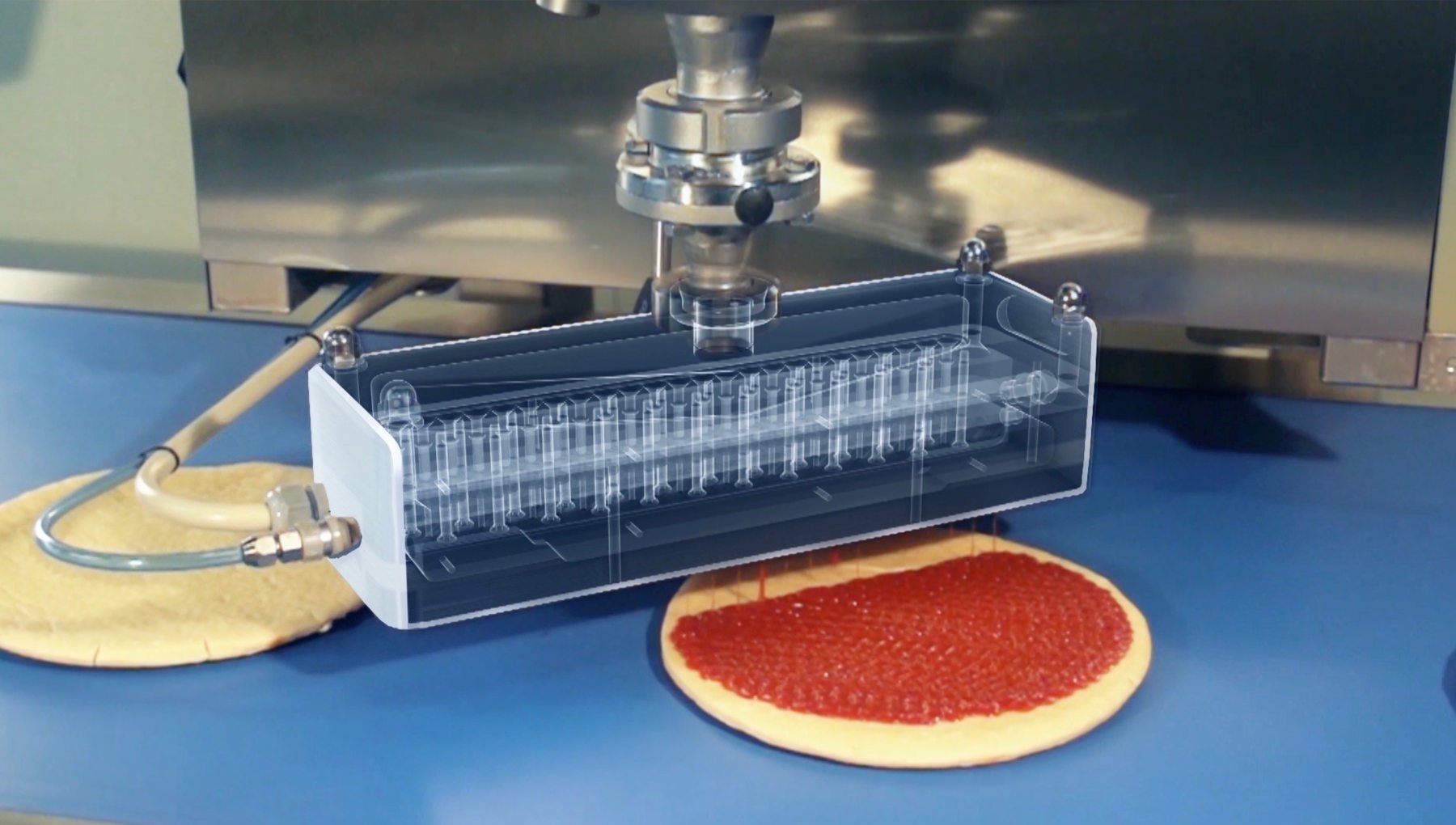

FoodJet applies a thin layer of material over the complete surface of the muffin. The array of nozzles of the depositing head covers a controllable layer. This will give every bite a similar sensation. And it makes the product look so much better.

More advantages of jetting chocolate

What if products are not aligned? No problem! We can use a vision system to compensate for any offset in position. This way, we can guarantee a centered deposit of the material, no matter how the muffins are positioned on the muffin line. Want to learn more about FoodJet's unique technology?

Learn all about our technology

Looking for similar applications for your industrial muffin line?

FoodJet's depositing solutions are always tailored to fit the needs and preferences of your muffin production process. This means that no machine is exactly alike! This enables us to produce depositing solutions for a wide range of materials. Take a look at our similar applications:

Typical system setup

A FoodJet muffin depositor could look as follows in your industrial muffin production line:

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!