Surface filling with the depositors of FoodJet

Fill or cover the entire surface of your product with the depositors of FoodJet. Our depositors allow you to improve the efficiency of your production process.

Waste of materials is reduced with our accurate vision technology. At the same time, this technology makes it possible for you to produce your products at high production speeds while maintaining an outstanding visual quality.

All of our food depositors for surface filling or surface covering are constructed based on your product and material.

Depending on your process and production line, either frame is adapted to your requirements. Get in touch with us to discuss the posibilities.

Cover all surfaces

Do you want to fill the entire surface of your product? FoodJet systems are specially designed to apply materials in an even layer. Where other food depositors resign FoodJet steps in:

- High production speeds are not an issue; our systems can handle them all.

- Even if there are inclusions in your material, our nozzles will ensure a smooth surface.

- Unmatched visual depositing quality

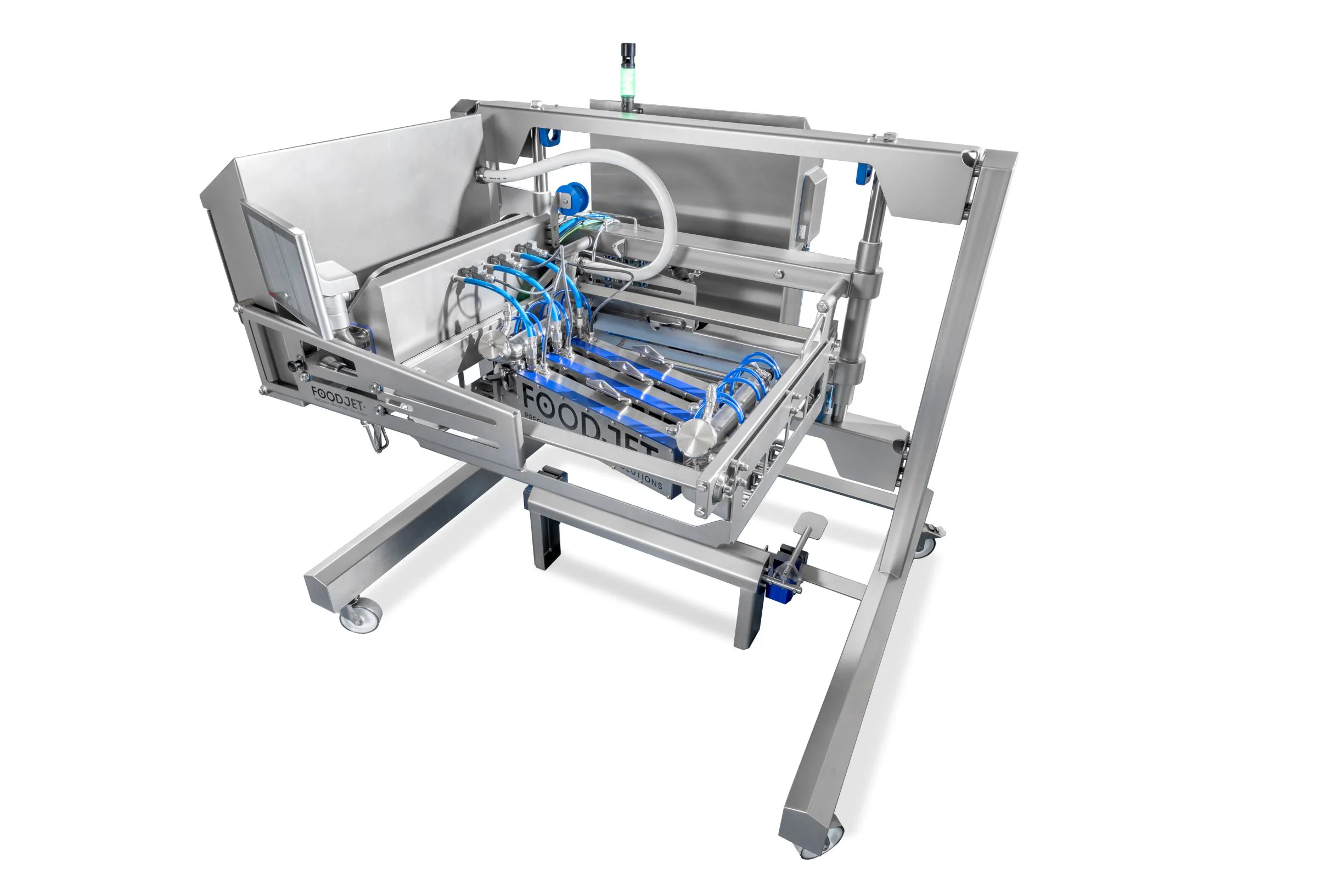

A frame for every situation

Typically, FoodJet depositors come in two frame types:

- Movable depositors - these are C-shaped frames that slide over an existing conveying system

- Stationary depositors- these frames are mounted to the floor in a fixed position

Depending on your process and production line, either frame is adapted to your requirements.

Producing peculiar shapes?

No problem! The FoodJet vision system will find and detect any shape. Our food depositor will cover the surface exactly as you’d like. You define the sauce free edge and save it in the product recipe. The proprietary FoodJet Free Form Pattern Generator software will make sure your product will not have any sauce on the edge. And if you change product shapes, you just upload the corresponding recipe and you are good to go. No mechanical change-overs whatsoever.

Typical application: Flammkuchen/Tarte flambée

Check out these applications

Your product is not in this list? No problem send us a message and we will help you out.

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!