Chocolate decorations with our tempered chocolate machine

Today’s producers want the flexibility to change seasonal decorations or offer branded products to their customers. FoodJet tempered chocolate depositors make this possible by allowing you to run various designs at the same time, without the need for mechanical changeovers.

Want to learn more about the tempered chocolate machines of FoodJet?

Not a one-shot depositor

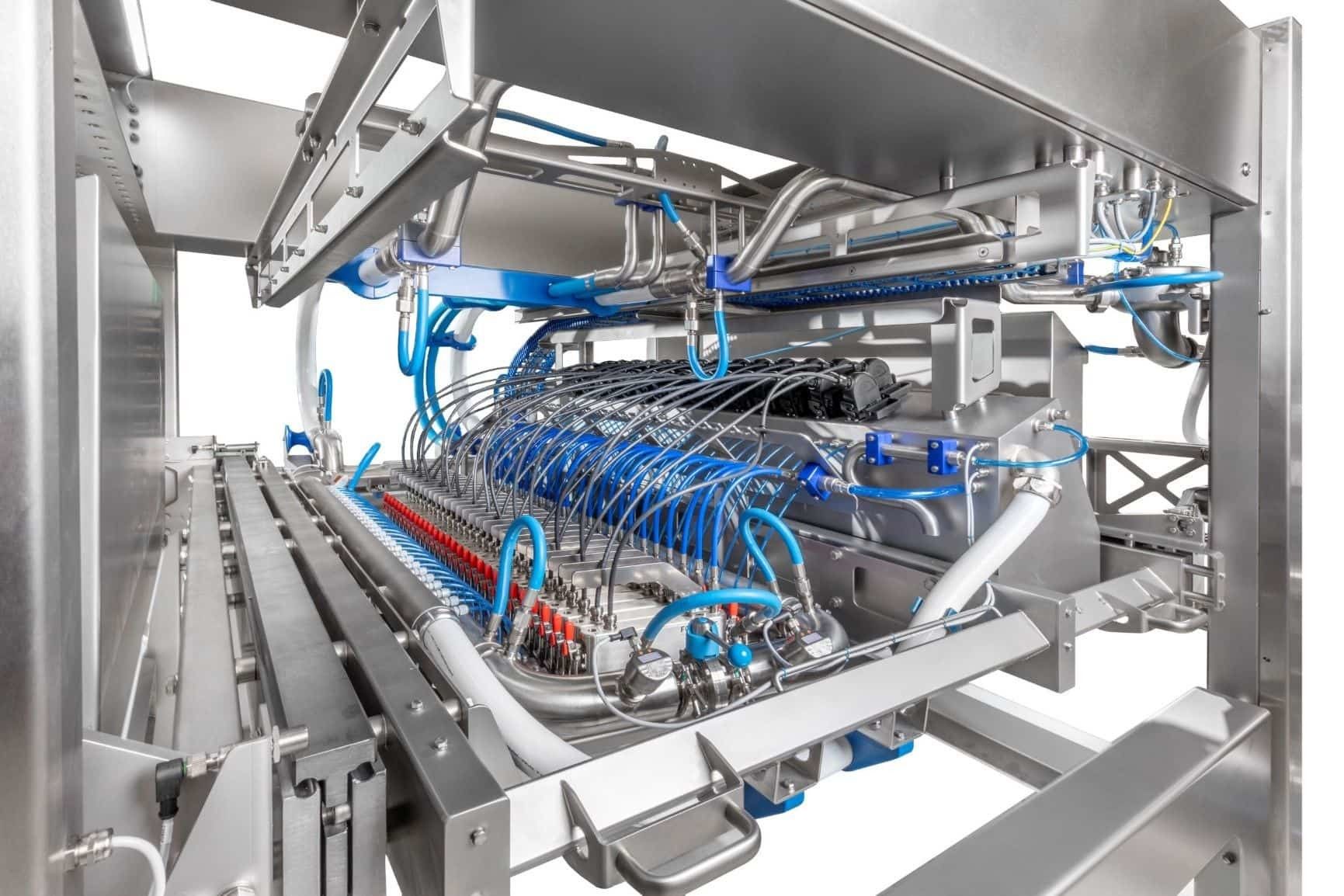

The FoodJet tempered chocolate machine is not a one-shot depositor. It uses an array of small nozzles that are individually controlled. Therefore, with our industrial chocolate machinery, you can vary the amount of material you apply in each section of a mould or product. This allows you to create unique and personalised tempered chocolate decorations.

Depositing tempered chocolate

If you work with a high-value material like tempered chocolate, it is essential to control the complete process:

- Maintain the right temperature

- Minimize spillage

- Prevent contamination

Maintain the right temperature

Once the chocolate is tempered, you want to make sure you keep it at the right temperature. FoodJet's industrial chocolate machine uses double jacketed hoses or piping throughout the system. The water for this closed circuit is provided by the FoodJet PUL supply system. It has its own heat exchanger to make it a stand-alone process with the tempered chocolate depositor. That's how we create the best tempered chocolate decorations for your products.

Minimize spillage

You do not want your chocolate to go to waste. Depending on your process and products, we can use cameras to prevent this from happening. You don’t even need to align your products. The vision system will locate the exact position. Making sure that the depositing material ends up on your product – and not on your conveyor belt.

Prevent contamination

FoodJet uses a closed-loop system. Traditional enrobing systems use a collection tank to recuperate material. Chocolate, which was not deposited on the product, is caught and returned to the supply system. These open loops leave a lot of room for contamination. Pieces of products or foreign materials could fall into the process.

Closed-loop tempered chocolate depositor

All the chocolate that is supplied to the FoodJet system either ends up on your product, or it returns to the supply system without making contact with the surrounding environment. This is a safe way to increase the yield of your material and protect your tempered chocolate decorating process.

Tempered chocolate decorations on biscuits

Let us demonstrate how FoodJet's tempered chocolate machine precisely deposits tempered chocolate decorations in the shape of a deer on biscuits. Explore the innovative possibilities with FoodJet today.

Did you like this video?

Big and small chocolate depositing solutions

Whether you are an entry-level producer or you are running a large scale production line, FoodJet has the perfect tempered chocolate machine for you. Our depositing systems are customizable. Together we will find the right industrial chocolate machine for your production line.

Not only are our depositors customizable, they are also suitable to scale to fit large production lines. Our engineers will design the system that fits your requirements.

Interested in learning more about FoodJet, our technology, or our machines? Visit our frequently asked questions page. Get in touch with one of our engineers to discuss the possibilities of FoodJet's chocolate machinery.

Typical system configuration

Do you want to discover how our tempered chocolate machines can help you improve your production?

Give us a call or e-mail us!

You want to increase accuracy, improve line speed and

add an unique touch to your product? Let us help you!